Over the years D/F has worked exclusively with Alcotec aluminum wires due to their superior quality and consistency. There are actually several D/F Machine Specialties torches in the Alcotec lab from its Water-Cooled Pistol Gun used by trailer manufacturers to its 1000 amp BIG MIG Machine Barrel for up to 1/4" aluminum wires.

A fundamental difference between arc welding of steel and aluminum is the evaluation method used during the filler alloy selection process. There are many aluminum base materials that can be welded successfully with any number of different filler alloys. The base alloy referenced in the above question, 6061-T6 for instance, is commonly welded with at least four totally different filler alloys and can be welded successfully with even more.

So how do we choose the filler alloy that will work best for us? The answer to this question is that we are unable to select, with any certainty, the most appropriate filler material without an understanding of the welded component application and expected performance in service. When we choose an aluminum filler alloy, we need to ask ourselves, which of the variables associated with weld performance are of most importance. Also, we must realize that selection of a filler alloy that is not recommended for our specific application may result in inadequate service performance and possibly premature failure of the welded joint. Filler alloys for arc welding aluminum are evaluated against the following variables:

- Ease of Welding: This is the relative freedom from weld cracking. By use of hot cracking sensitivity curves for the various aluminum alloys, and through the consideration of dilution between filler alloy and base alloy, we can establish the filler alloy / base alloy crack sensitivity rating.

- Strength of Weld Joint: Consideration of the tensile strength of groove welds and shear strength of fillet welds, when welded with different filler alloys, can prove to be extremely important during welding design. Different filler alloys, which may both exceed the as-welded tensile strength of the base material, can be significantly different in shear strength performance.

- Ductility: A consideration if forming operations are to be used during fabrication and may also be a design consideration for service if fatigue and/or shock loading are of importance.

- Corrosion Resistance: A consideration for some environmental conditions and are typically based on exposure to fresh and salt water.

- Sustained Temperature Services: The reaction of some filler alloys at sustained elevated temperature (above 150 deg. F). This may promote premature component failure due to stress corrosion cracking.

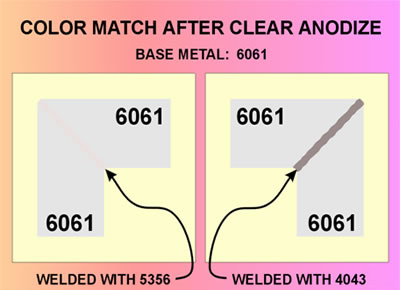

- Color Match Base: Alloy and filler alloy color match after anodizing can be of major concern in some cosmetic applications

- Post Weld Heat Treatment: The ability of the filler alloy to respond to post weld heat treatment associated with filler alloy chemistry and joint design.

As an example of the extent and complexity of this situation, we can take one of the many aluminum base alloys and three of the many applications in which this base material may be used. If we consider the base alloy in the original question, 6061-T6, and its use in the following different applications, we can appreciate that the filler alloy that we select for welding can seriously affect the component’s performance.

As an example of the extent and complexity of this situation, we can take one of the many aluminum base alloys and three of the many applications in which this base material may be used. If we consider the base alloy in the original question, 6061-T6, and its use in the following different applications, we can appreciate that the filler alloy that we select for welding can seriously affect the component’s performance.

- Using 6061-T6 tubing for hand railing that is to be clear coat anodized after welding. In this application we need to select the filler alloy that is going to provide us with the best color match after anodizing. With color match as our prime consideration, the most appropriate filler for this application is alloy 5356. If we were to select filler alloy 4043, 4047, or 4643, which are often shown as being suitable for this base material, we would find that after anodizing, our weld would become dark gray in color and would not provide a suitable match to the bright silver appearance of the hand rail tubing (see right).

- Using 6061-T6 extruded angle bar as a welded attachment bracket for a heating component that will be operating consistently at 250 deg. F. In this application we would investigate those filler alloys that are suitable for elevated temperature service. We may consider 5554, 4043, or 4047 filler alloys, which are all suitable for temperature service applications. If we were to use the 5356, 5183, or 5556 filler alloys, which are often shown as being suitable for this base material, we would introduce the possibility of sensitization of the magnesium in these alloys and run the risk of stress corrosion cracking and premature failure of the welded component.

- Using 6061-T6 to fabricate a large safety-critical lifting device that is required to undergo extensive welding during fabrication, followed by postweld solution heat treatment and artificial aging in order to restore some strength and return the structure to the -T6 temper. In this application our concerns may be the strength of our weld after it has been exposed to postweld heat treatment. Most filler alloys commonly used for welding this base material will not respond favorably to this type of heat treatment. The 5356, 5183, and 5556 filler alloys are non-heat treatable alloys which can undergo undesirable changes if subjected to this form of heat treatment. The 4043 filler alloy, on its own, is non-heat treatable and would be totally dependent on dilution with the base material in order to achieve any significant response to the heat treatment. In this application we should seriously consider the use of filler alloy 4643, which is a heat treatable filler alloy and will, therefore, respond to the heat treatment after welding and provide a weld of comparable strength to that of the base material.

Making The Choice – We should evaluate, in detail, each of the variables specific to our application in order to establish the most suitable filler alloy. Fortunately, there are aluminum filler alloy selection charts available which have been developed to assist us with the most appropriate choice of filler alloy. These charts have been developed through careful consideration of all the variables and often provide a rating system for each variable to help us with the selection process. If we are unsure as to the most suitable filler alloy, we should consult the experts