Water-Cooled 70° ID Bore Torch

Drawings Accessories More Info

Overview

The D/F Model CTW59 70 Degree torch for 3" IDs is durable, light weight, and has excellent cooling within the internal water passages, thus eliminating the need for gaskets or O-rings. Gun and cable assemblies are shipped from the factory assembled complete with a current tip and gas nozzle that are selected by the user. Due to the fact that there are numerous IDs and varying requirements for each application, this series of D/F torches is tailored to fit each of these unique applications and falls under the "specialties", hence the name D/F Machine Specialties, and requires a 2-3 week delivery upon receipt of a purchase order. We highly recommend that customers also purchase a backup torch to reduce downtime due to the fact that these are custom torches and have a 2-3 week delivery upon receipt of order.

Features

- For Small 3" Bore IDs, .035"-.045" Wire

- GMAW Process With Short Arc, Spray Transfer, Pulse Modes

- Weld in All Positions – Horizontal, Vertical, or Inverted

- Weld with All Base and Filler Metals

- 75% Time Reduction vs. Hand Welding

- More Consistent Weld Build-up

- Reduce Machining Time by Up to 50%

- Extend the Life of Consumables

Model Explanation

- CTW - Curved, Threaded Current Tip - Water-Cooled

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) |

COOLING REQUIRED |

RECOMMENDED WIRE DIA. | INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| CTW59 | 450 amps | 2 lbs | 1 gallon/min | .035"-.045" | 372 |

Barrel Dimensions

| MODEL | BODY LENGTH | DIAMETER OF BODY HANDLE |

|---|---|---|

| 70° CTW59 | 8"-32" | 1.450" |

Ordering Information

| DESCRIPTION | CODE NO. | |||||

| 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | |

| CTW59 | 15759-3 | 15759-4 | 15759-5 | 15759-6 | 15759-7 | 15759-8 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| 70° CTW59 | 372 |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| CTW59 | 15759 | 15759 | 15759 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Choosing the Proper Chiller for Your Application |

|

| Torch Connection Options | |

| W/C ID Bore Torches One-Sheet |

Utility Station #45196

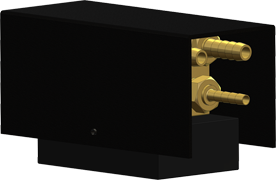

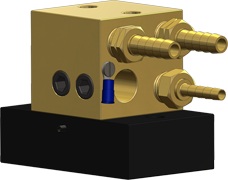

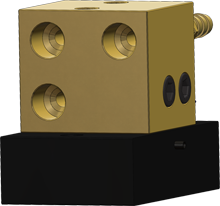

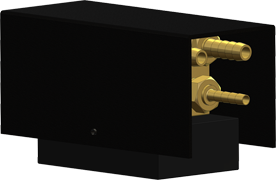

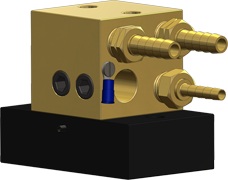

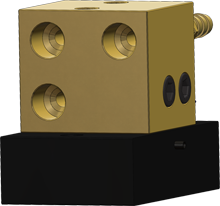

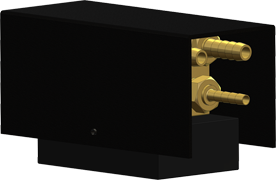

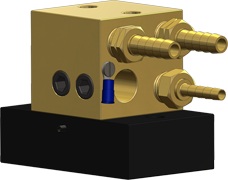

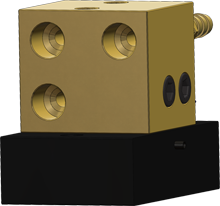

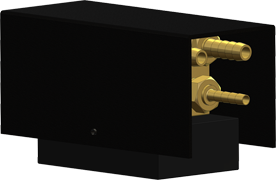

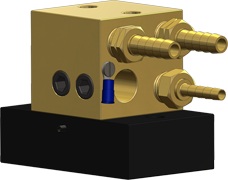

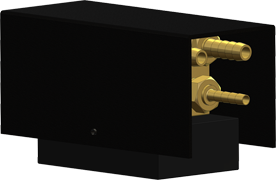

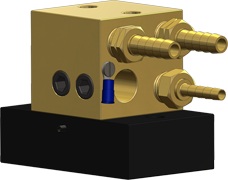

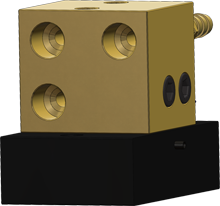

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

More Info

The versatile MIG Water-Cooled Small ID Bore Torches can be used for a wide range of applications. These small inner diameter bore torches may be connected to all manufactures' wire feeders and power sources. With the various torch sizes, angles and lengths available, an ID torch selection may be made to suit individual requirements. These models are rugged, field-proven weld heads for use in small diameter pipe and other limited radial clearance applications. They are heavy duty in design and can withstand upwards of 600 degree preheat. These bore torches are designed to extend into as small as a 3" ID bore or valve and weld by the GMAW process.

In order to provide proper cooling and optimum equipment performance, a properly sized liquid chiller is essential. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them, and as you know a heavy duty water-cooled production torch needs to be chilled. When working with preheat in a small ID bore a Miller Coolmate 1, Coolmate 3, Coolmate V3, Coolmate 3.5, Coolmate 3X, Coolmate 4 or Lincoln Cool Arc 40, Cool Arc 55 will not work. Not only are their reservoirs too small on these units but they have little or no cooling capacities. Because of the extreme conditions you must have a real chiller with at least a 10-25 gallon reservoir and a 55,000 BTU cooling capacity. The torch's coolant must be kept within the 50-60 degree temperature range at all times. Our chiller one-sheet will help you select the correct chiller for your application. For more information about chillers visit our recommended water chillers page. Additional protection for the torch is needed when working with preheat. We recommend a high temperature fiberglass wrap to wrap the full length of the body and to protect it from the reflective heat. This high temperature tape is heat, flame and fire resistant. This fiberglass (fibreglass) knitted tape is fabricated from high quality type E fiberglass that will not burn and will withstand continuous exposure to temperatures of 1000°F / 520°C.

By welding the bore with a D/F small ID bore torch you can achieve a very even and consistent weld bead that can easily be machined out to fit the new pins or bushings, in contrast to welding by hand were you might have high and low spots that need extra machining or extra welding which takes time and money. Because of our superior water-cooling the torches are design to withstand the extreme conditions and duty cycles. The D/F automated bore torches are superior to hand-welding. They are faster, provide smoother welds, and allow you to access hard-to-reach or small ID bores.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Water-Cooled 70° ID Bore Torch

Drawings Accessories

Overview

The D/F Model CTW67 70 Degree torch is durable, light weight, and has excellent cooling within the internal water passages, thus eliminating the need for gaskets or O-rings. Gun and cable assemblies are shipped from the factory assembled complete with a current tip and gas nozzle that are selected by the user. Due to the fact that there are numerous IDs and varying requirements for each application, this series of D/F torches is tailored to fit each of these unique applications and falls under the "specialties", hence the name D/F Machine Specialties, and requires a 2-3 week delivery upon receipt of a purchase order. We highly recommend that customers also purchase a backup torch to reduce downtime due to the fact that these are custom torches and have a 2-3 week delivery upon receipt of order.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- For Small 4" Bore IDs, .035"-.045" Wire

- GMAW Process With Short Arc, Spray Transfer, Pulse Modes

- Weld in All Positions – Horizontal, Vertical, or Inverted

- Weld with All Base and Filler Metals

- 75% Time Reduction vs. Hand Welding

- More Consistent Weld Build-up

- Reduce Machining Time by Up to 50%

- Extend the Life of Consumables

Model Explanation

- CTW - Curved, Threaded Current Tip - Water-Cooled

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) |

COOLING REQUIRED |

RECOMMENDED WIRE DIA. | INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| CTW67 | 450 amps | 2 lbs | 3 quarts/min | .035"-.045" | 370 |

Barrel Dimensions

| MODEL | BODY LENGTH | DIAMETER OF BODY HANDLE |

|---|---|---|

| 70° CTW67 | 8"-32" | 1.450" |

Ordering Information

| DESCRIPTION | CODE NO. | |||||

| 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | |

| CTW67 | 15767-3 | 15767-4 | 15767-5 | 15767-6 | 15767-7 | 15767-8 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| 70° CTW67 | 370 |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| CTW67 | 15767 | 15767 | 15767 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Choosing the Proper Chiller for Your Application |

|

| Torch Connection Options | |

| W/C ID Bore Torches One-Sheet |

Utility Station #45196

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Water-Cooled 55° ID Bore Torch

Drawings Accessories

Overview

The D/F Model CTW68 55 Degree torch is durable, light weight, and has excellent cooling within the internal water passages, thus eliminating the need for gaskets or O-rings. Gun and cable assemblies are shipped from the factory assembled complete with a current tip and gas nozzle that are selected by the user. Due to the fact that there are numerious IDs and varying requirements for each application, this series of D/F torches is tailored to fit each of these unique applications and falls under the "specialties", hence the neme D/F Machine Specialties, and requires a 2-3 week delivery upon receipt of a purchase order. We highly recommend that customers also purchase a backup torch to reduce downtime due to the fact that these are custom torches and have a 2-3 week delivery upon receipt of order.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- For 4" Bore IDs, .035"-1/16" Wire

- GMAW Process With Short Arc, Spray Transfer, Pulse Modes

- Weld in All Positions – Horizontal, Vertical, or Inverted

- Weld with All Base and Filler Metals

- 75% Time Reduction vs. Hand Welding

- More Consistent Weld Build-up

- Reduce Machining Time by Up to 50%

- Extend the Life of Consumables

Model Explanation

- CTW - Curved, Threaded Current Tip - Water-Cooled

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) |

COOLING REQUIRED |

RECOMMENDED WIRE DIA. | INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| CTW68 | 450 amps | 2 lbs | 3 quarts/min | .035"-1/16" | 389 |

Barrel Dimensions

| MODEL | BODY LENGTH | DIAMETER OF BODY HANDLE |

|---|---|---|

| 55° CTW68 | 8"-32" | 1.450" |

Ordering Information

| DESCRIPTION | CODE NO. | |||||

| 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | |

| CTW68 | 15768-3 | 15768-4 | 15768-5 | 15768-6 | 15768-7 | 15768-8 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| 55° CTW68 | 389 |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| CTW68 | 15768 | 15768 | 15768 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Choosing the Proper Chiller for Your Application |

|

| Torch Connection Options | |

| W/C ID Bore Torches One-Sheet |

Utility Station #45196

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Water-Cooled Mighty MIG ID Bore Torch

Drawings Accessories

Overview

The D/F "Mighty MIG" 55° torch with a mini front end is durable, light weight, and has excellent cooling within the internal water passages, thus eliminating the need for gaskets or o-rings. Gun and cable assemblies are shipped from the factory assembled complete with a current tip and gas nozzle that are selected by the user. Due to the fact that there are numerous IDs and varying requirements for each application, this series of D/F torches is tailored to fit each of these unique applications and falls under the "specialties", hence the name D/F Machine Specialties, and requires a 2-3 week delivery upon receipt of a purchase order. We highly recommend that customers also purchase a backup torch to reduce downtime due to the fact that these are custom torches and have a 2-3 week delivery upon receipt of order.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- For 6.5" Bore IDs, Up to 1/16" Wire

- GMAW Process With Short Arc, Spray Transfer, Pulse Modes

- Weld in All Positions – Horizontal, Vertical, or Inverted

- Weld with All Base and Filler Metals

- 75% Time Reduction vs. Hand Welding

- More Consistent Weld Build-up

- Reduce Machining Time by Up to 50%

- Extend the Life of Consumables

Model Explanation

- HTC - Heavy Duty, Threaded Tip, Curved

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) |

COOLING REQUIRED |

RECOMMENDED WIRE DIA. | INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| HTC | 500 amps | 2.5 lbs | 3 quarts/min | Up to 1/16" | 350MM HTC-16 |

Barrel Dimensions

| MODEL | BODY LENGTH | DIAMETER OF BODY HANDLE |

|---|---|---|

| HTC | 8"-32" | 1.500" |

Ordering Information

| DESCRIPTION | CODE NO. | ||||||

| 4 Ft. | 5 Ft. | 6 Ft. | 8 Ft. | 10 Ft. | 12 Ft. | 15 Ft. | |

| HTC | 11377-4 | 11377-5 | 11377-6 | 11377-8 | 11377-10 | 11377-12 | 11377-15 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| HTC | 350MM HTC-16 |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| HTC | 11377 | 11377 | 11377 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Choosing the Proper Chiller for Your Application |

|

| Torch Connection Options | |

| W/C ID Bore Torches One-Sheet |

Utility Station #45196

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

W/C 55° ID Bore Torch - External Casing

Drawings Accessories

Overview

The D/F Model HTC-E 55 Degree torch is durable, light weight, and has excellent cooling within the internal water passages, thus eliminating the need for gaskets or O-rings. Gun and cable assemblies are shipped from the factory assembled complete with a current tip and gas nozzle that are selected by the user. Due to the fact that there are numerous IDs and varying requirements for each application, this series of D/F torches is tailored to fit each of these unique applications and falls under the "specialties", hence the name D/F Machine Specialties, and requires a 2-3 week delivery upon receipt of a purchase order. We highly recommend that customers also purchase a backup torch to reduce downtime due to the fact that these are custom torches and have a 2-3 week delivery upon receipt of order.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- For 10"-15" Bore IDs, Up to 1/8" Wire

- GMAW Process With Short Arc, Spray Transfer, Pulse Modes

- Weld in All Positions – Horizontal, Vertical, or Inverted

- Weld with All Base and Filler Metals

- 75% Time Reduction vs. Hand Welding

- More Consistent Weld Build-up

- Reduce Machining Time by Up to 50%

- Extend the Life of Consumables

Model Explanation

- HTC-E - Heavy Duty, Threaded Tip, Curved - External Casing

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) |

COOLING REQUIRED |

RECOMMENDED WIRE DIA. | INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| HTC-E | 600 amps | 2.5 lbs | 3 quarts/min | Up to 1/8" | 371 HTC-E |

Barrel Dimensions

| MODEL | BODY LENGTH | DIAMETER OF BODY HANDLE |

|---|---|---|

| HTC-E | 8"-32" | 1.500" |

Ordering Information

Internal Conduit (through torch body)

| DESCRIPTION | CODE NO. | ||

|---|---|---|---|

| Model HTC (Threaded Tip) | 10 Ft. Casing | 12 Ft. Casing | 15 Ft. Casing |

| Short 3" W/C Nozzle. | 17184 | 17187 | 17190 |

| Intermediate 4" W/C Nozzle. | 17185 | 17188 | 17191 |

| Long 5" W/C Nozzle. | 17186 | 17188 | 17192 |

Internal Conduit (through torch body)

| DESCRIPTION | CODE NO. | ||

|---|---|---|---|

| Model HTC-A (Threaded Tip) | 10 Ft. Casing | 12 Ft. Casing | 15 Ft. Casing |

| Short 3" W/C Nozzle. | 17283 | 17286 | 17289 |

| Intermediate 4" W/C Nozzle. | 17284 | 17287 | 17290 |

| Long 5" W/C Nozzle. | 17285 | 17288 | 17291 |

External Conduit

| DESCRIPTION | CODE NO. | ||

|---|---|---|---|

| Model HTC-E (Threaded Tip) | 10 Ft. Casing | 12 Ft. Casing | 15 Ft. Casing |

| Short 3" W/C Nozzle. | 15383 | 15386 | 15389 |

| Intermediate 4" W/C Nozzle. | 15384 | 15387 | 15390 |

| Long 5" W/C Nozzle. | 15385 | 15388 | 15391 |

External Conduit

| DESCRIPTION | CODE NO. | ||

|---|---|---|---|

| Model HTCE-A (Threaded Tip) | 10 Ft. Casing | 12 Ft. Casing | 15 Ft. Casing |

| Short 3" W/C Nozzle. | 15422 | 15425 | 15428 |

| Intermediate 4" W/C Nozzle. | 15423 | 15426 | 15429 |

| Long 5" W/C Nozzle. | 15424 | 15427 | 15430 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| HTC-E & HTCE-A | 371 HTC-E |

| HTC | 368 HTC |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| HTC 3" | 17184 | 17184 | 17184 |

| HTC 4" | 17185 | 17185 | 17185 |

| HTC 5" | 17186 | 17186 | 17186 |

| HTC-A A3" | 17283 | 17283 | 17283 |

| HTC-A A4" | 17284 | 17284 | 17284 |

| HTC-A A5" | 17285 | 17285 | 17285 |

| HTC-E 3" | 15383 | 15383 | 15383 |

| HTC-E 4" | 15384 | 15384 | 15384 |

| HTC-E 5" | 15385 | 15385 | 15385 |

| HTCE-A A3" | 15422 | 15422 | 15422 |

| HTCE-A A4" | 15423 | 15423 | 15423 |

| HTCE-A A5" | 15424 | 15424 | 15424 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Choosing the Proper Chiller for Your Application |

|

| Torch Connection Options | |

| W/C ID Bore Torches One-Sheet |

Utility Station #45196

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.