View Your D/F MIG Gas Nozzle:

View Your D/F Ceramic TIG Nozzle:

View Your D/F Metallic TIG Nozzle:

View Your D/F MIG Nozzle Body:

D/F Mini Nozzle Arrangement

D/F MIG & TIG Gas Nozzles & Cups - General Information

D/F Machine Specialties genuine American made MIG and TIG copper and alumina gas nozzles deliver the performance and reliability you need to minimize your production costs while maximizing welding efficiencies! D/F’s gas nozzles are made domestically in the United States and our copper is also purchased domestically. Wouldn’t you prefer to know that when buying an American product it is not only manufactured in America but the raw materials that make up the product also come from America? Many large manufacturers with robotic assembly lines have not only discovered the advantages of D/F’s superior built torches, but also the advantages of using D/F Machine Specialties genuine American made nozzles which reduce down time for tip changes and increase productivity.

We at D/F know that nozzles get used and abused in the field. For cleaning of threads, and re-tapping & cleaning damaged threads, D/F manufactures its own line of nozzle thread chaser taps which can be found here.

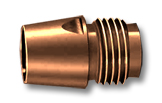

D/F MIG Gas Nozzles

D/F MIG Gas Nozzles & Gas Cups are precision machined to stringent standards for excellent fit and long life. We manufacture a complete line of standard size C122 DHP MIG gas nozzles, gas cups, nozzle thread seals for sub-arc applications, as well as any custom nozzle configuration you may need. We can make any style of gas nozzle, in any quantity, for any type of application. Each requirement is quoted quickly and accurately to meet your needs. Our MIG gas nozzles are self insulated, standard and heavy duty in a wide variety of sizes for most every semi-automatic, automatic and robotic welding application.

Each requirement is quoted quickly and accurately to meet your needs.

D/F TIG Gas Nozzles

D/F Alumina & Ceramic TIG Nozzles & Cups, made from high strength alumina & ceramic materials, have very good electrical insulating properties; exceptionally high impact resistance, heat resistance and thermal conductivity; and resist splatter build-up. They are recommended for most welding operations except for use in confined areas.

D/F Nozzles (also called gas cups) provide a given amount of shielding gas coverage to the weld pool, according to their size (anywhere from 1/4- to 5/8-inch ID). For example, a smaller nozzle provides less gas coverage than a larger one. Nozzles also vary in price and performance.

The most cost effective are 90 or 95 percent alumina oxide nozzles, which work adequately for lower amperage applications. These nozzles, however, do not resist thermal shock on higher amperage applications very well and tend to deteriorate or crack and fall off.

Lava nozzles cost more than alumina oxide nozzles and are more resistant to cracking. These nozzles work well on medium to high amperage applications.

D/F Metallic TIG Nozzles are ideal for long lasting life and durability. These metallic TIG nozzles are ideal for tube mill applications. We manufacture a complete line of standard size C122 DHP TIG nozzles & cups, as well as any custom nozzle configuration you may need.

The bottom line when choosing TIG consumables is to look for factory OEM parts that provide you with the durability and performance you need. A wide variety of options exist for back caps, collets and collet bodies, gas lenses and nozzles, all of which offer distinct advantages, disadvantages and cost considerations. For less critical applications, the less expensive alumina nozzles provide adequate performance. However, if you need high performance, it is well worth your while to purchase more expensive, long-lasting lava nozzles or cups. Doing so minimizes the chance of consumable failures that could ultimately increase the cost for rework associated with weld inconsistencies.

Each requirement is quoted quickly and accurately to meet your needs.

Ordering Information

D/F MIG Gas Nozzles

| GUN MODEL | REF. | PART NO. | NOZZLE TYPE | OD (in.) | OD (mm) | ID (in.) | ID (mm) |

|---|---|---|---|---|---|---|---|

| NCM, HTM, NCC, HTC, MCW, MTW, all standard size DF Water Cooled Nozzles (front chrome barrels) |

1 | 10362 |

Copper Tapered | 63/64" | 25mm | 5/8" | 15.9mm |

| 2 | 10340 |

Copper Straight | 1" | 25.4mm | 3/4" | 19mm | |

| 3 | 19348 |

Copper Straight | 21/32" | 16.7mm | 1/2" | 12.7mm | |

| 4 | 10376 |

Copper Straight | 21/32" | 16.7mm | 1/2" | 12.7mm | |

| 5 | 10359 |

Copper Full Taper | 63/64" | 25mm | 5/8" | 15.9mm | |

| 6 | 10374 |

Copper Straight | 5/8" | 15.9mm | 7/16" | 11.1mm | |

| 7 | 14871 |

Nozzle Thread Seal (Sub-Arc) | 1" | 25.4mm | 5/8" | 15.9mm | |

| CTW59/67/68 ID Bore Torches |

8 | 40089-S |

Copper Straight | 1" | 25.4mm | 3/4" | 19mm |

| CTW, CCW, CW-T, CW-C, MCW, MTW | 9 | 16380 |

Copper Tapered | 7/8" | 22.2mm | 5/8" | 15.9mm |

| 10 | 16379 |

Copper Tapered | 7/8" | 22.2mm | 35/64" | 13.9mm | |

| 11 | 10368 |

Copper Tapered | 1-3/8" | 34.9mm | 3/4" | 19mm | |

| HTC-A, NCC-A HIGH CAPACITY |

12 | 18030 |

Copper Full Taper | 1-3/8" | 34.9mm | 11/16" | 17.5mm |

| 13 | 18031 |

Copper Full Taper | 1-3/8" | 34.9mm | 13/16" | 20.6mm | |

| 14 | 18032 |

Copper Full Taper | 1-3/8" | 34.9mm | 15/16" | 23.8mm | |

| 15 | 16748 |

Copper Straight | 1-3/8" | 34.9mm | 1" | 25.4mm | |

| 16 | 16749 |

Copper Tapered | 1-3/8" | 34.9mm | 11/16" | 17.5mm | |

| 17 | 16750 |

Copper Tapered | 1-3/8" | 34.9mm | 13/16" | 20.6mm | |

| 18 | 16751 |

Copper Tapered | 1-3/8" | 34.9mm | 15/16" | 23.8mm | |

| 19 | 14872 |

Nozzle Th'd Seal (Sub-Arc) | 1-3/8" | 34.9mm | 13/16" | 20.6mm | |

| "BIG MIG", "BIG TIG" | 20 | 10387 |

Copper Tapered | 1.706" | 43.3mm | 1" | 25.4mm |

| 21 | 10389 |

Copper Straight | 1.706" | 43.3mm | 1-1/4" | 31.8mm | |

| HTM-TDP, NCM18, HTM18 | 22 | 41667 |

Copper Tapered | 2-1/8" | 54mm | 7/8" | 22.2mm |

| 23 | 41668 |

Copper Straight | 2-1/8" | 54mm | 1.570" | 39.9mm |

D/F TIG Gas Nozzles

| GUN MODEL | REF. | PART NO. | NOZZLE TYPE | ID (in.) | ID (mm) |

|---|---|---|---|---|---|

| TM500, TM500B | 1 | 15895-A |

Size No. 4 Ceramic Alumina (Pink) | 1/4" | 6.4mm |

| 2 | 15896-A |

Size No. 6 Ceramic Alumina (Pink) | 3/8" | 9.5mm | |

| 3 | 15897-A |

Size No. 8 Ceramic Alumina (Pink) | 1/2" | 12.7mm | |

| 4 | 15898-A |

Size No. 10 Ceramic Alumina (Pink) | 5/8" | 15.9mm | |

| 5 | 15903 |

Metallic Conventional Welding | 5/8" | 15.9mm | |

| 6 | 15904 |

Metallic Conventional Welding | 3/4" | 19mm | |

| "BIG TIG" TM1000 | 7 | 15922 |

Ceramic | 13/16" | 20.6mm |

| "BIG TIG" TM1000 | 8 | 15907 |

Metallic Tube Mill | 13/16" | 20.6mm |

D/F MIG Nozzle Bodies

| GUN MODEL | REF. | NOZZLE TYPE | PART NO. |

|---|---|---|---|

| CTW, CCW, CW-T, CW-C, MTW | 1 | Normal Duty - Chrome Plated | 13197 |

| CTW, CCW, CW-T, CW-C, MTW | 1 | Medium Duty - Chrome Plated | 13198 |

| CW-T | 1 | Heavy Duty - Chrome Plated | 13196 |

| CTW, CCW, CW-T, CW-C, MTW | 1 | Light Duty - Chrome Plated | 16384 |

D/F Mini Nozzle Arrangement

| DESCRIPTION | DIMENSION | PART NO. |

|---|---|---|

| Washer | 40080 | |

| Nut | 40081 | |

| Centering Disc | 40082 | |

| Adapter | 40083 | |

| Gas Nozzle | 7/16" (11.1mm) I.D. | 40085 |

| Gas Nozzle | .500" (12.7mm) I.D. | 40086 |

| Insulation Tube - Gas Nozzle | 40084 | |

| Current Tip | .030" (.8mm) Tapered | 10909 |

| Current Tip | .035" (.9mm) Tapered | 10910 |

| Current Tip | .045" (1.2mm) Tapered | 10911 |

| Current Tip | .052" (1.4mm) Tapered | 10912 |

| Current Tip | 1/16" (1.6mm) Tapered | 10913 |

The Advantages of D/F MIG & TIG Gas Nozzles

American Made

100% of our products are manufactured right here at our facilities, from the American made raw materials to the final product. Factory automation including robotic machining processes and vision inspection systems yields precision and high quality components.

Less Down Time

High quality, high performance equipment means less down time for repairs, and less changing out of consumable components.

The buzzwords, “Increased Productivity”, “Reduced Down Time”, “Continuous Improvement”, “Share Price”, “ROI”, have all mandated a constant search for what is the D/F way to keep automated welding equipment and facilities running at peak performance.

Shipping Products Globally

We deliver welding equipment to the Automotive, Shipbuilding, Steel Service, Mining, Metal Fabrication, Construction, Energy, and General Manufacturing industries.

Custom Manufacturing - Special Order Parts

If you’re looking for a part not listed on our website or in our catalog, be sure to call us. We fabricate special order parts and do limited production runs of torches, nozzles, tips and consumables. D/F continually adds new products to our listings and some parts may not be listed in our catalog.

Limited Production Runs - Hard to Find Parts for Older Equipment

D/F has a wealth of knowledge, dating back to 1940’s, that includes engineering drawings, programs and use specifications for older equipment, parts and consumables.

Gas Nozzle Cleaning & Maintenance

One of the most important—and simplest—ways to create strong welds is to properly maintain your welding equipment. Taking care of your torch does not require a great deal of effort, and it can save you significant time and money in the long run with equipment longevity, weld quality, and performance. Proper short term torch maintenance will help you prevent some common welding errors, avoiding costly repairs on improperly maintained or neglected equipment. Depending on the type of welding equipment you’re using, the maintenance required will be different. Stick (SMAW) welding equipment requires very little maintenance, while MIG (GMAW) and TIG (GTAW) welders need a bit more care and attention to stay in proper shape. The torch, contact tip, gas nozzle, and spatter disc work together to facilitate the necessary electrical conductivity and gas dispersion for the MIG process to occur, and proper care is important to maintain troublefree welding performance. You won’t be able to weld properly if these elements of your system aren’t kept in top shape.

Regular Inspection of MIG Equipment

Wire welders (MIG and/or flux-cored welding) include many peripheral items—the gun liner, gun contact tips, gas nozzles, the water/out & power cable, water-in hose & gas hose, gas diffuser/spatter disc, insulation tubes, etc.—and therefore require regular care and attention. It should be noted to always unplug the machine before performing any maintenance tasks. A MIG gun has to be inspected and cleaned during every shift change, and during every change of a contact tip, gas nozzle, spatter disc, or liner. The tips, nozzles, spatter discs, and liners themselves should be checked, changed, and cleaned regularly to prevent spatter buildup which leads to lower quality welds, and will even decrease torch life.

Resistance Heating – Torch Damage, Reduces Consumable Life

Copper starts to break down once its temperature exceeds 200 degrees. Keeping the gas nozzle clean is an important measure for several reasons. A gas nozzle with threads dirty from spatter buildup or oxidization will allow for significantly decreased metal to metal (copper to copper) contact when the gas nozzle is threaded back into the torch. This reduced contact with the copper front of the water-cooled nozzle will decrease the amount of cooling on the gas nozzle. More importantly, however, is the fact that the lack of contact will cause resistance heating. Without a clean connection, the electrical current that passes through the gap between the threads of the gas nozzle and water-cooled nozzle will turn into heat, causing the front of the torch to be preheated. Further, a torch can be overheated by not threading a copper gas nozzle all the way up so that the copper gas nozzle is not seated on the water-cooled nozzle’s copper front; resistance heating will also occur if the gas nozzle is not seated and snug tight. Resistance heating is a great threat to the life of the torch, causing consumables to be used up prematurely, and even causing damage to the torch itself.

Preventing Spatter Buildup in Gas Nozzles

The gas nozzle, which helps to shield the weld, often becomes filled with spatter while welding. It is important to keep the nozzle clean in order to avoid inhibiting the flow of gas and preventing your ability to weld. Using a nozzle dip or anti-spatter will help keep the nozzle clean. Similar to the consistency of jelly, a product referred to as nozzle dip can help prevent spatter from sticking to the nozzle. Simply dip the nozzle in the product every once in a while welding to reduce the buildup of spatter. However, don’t fully submerge the entire nozzle, you don’t want to clog the torch or cut off the gas, just dip the tip. Also, store the nozzle in the manufacturer’s packaging to prevent damage; if you toss it in a bin or other container, it may get dented or scratched, creating defect areas that can collect spatter or damage threads.

The following links feature various products for nozzle cleaning, maintenance, and prevention of spatter buildup:

- All Products: www.weldaid.com

- Nozzle Kleen: http://weldaid.com/nozzle-kleen/

Cleaning Spatter and Reconditioning Nozzles

There are various methods for cleaning gas nozzles when spatter does end up collecting in them. Remove the gas nozzle to inspect it. A spatter-full or damaged nozzle has to be wire brushed with a hand drill or lathe with a wire wheel brush. Thorough cleaning would include brushing the outside and inside flat surfaces, brushing the edges, and brushing out the threads. Once cleaned, a gas nozzle should be free of surface inconsistencies, and the threads should be clean enough to allow the copper nozzle to be threaded back onto the chrome water-cooled nozzle by hand. It is important to remember that after cleaning out the nozzle, blow it out with air to remove any metallic or foreign particles that might prevent a clean thread connection.

Removing a Seized Gas Nozzle Properly

If the gas nozzle is not properly cleaned, the operator will most likely use a large wrench on it to force it up onto the chrome water-cooled nozzle (front of the torch). This will seize up the gas nozzle in the torch, and will not come out without damaging the torch. In an attempt to remove a seized nozzle, a large wrench will again have to be used to remove the gas nozzle, and will end up tearing the front end off of the torch. If a gas nozzle cannot be threaded up by hand, it should not be put on the torch.

In case a gas nozzle does seize up in the front of the chrome water-cooled nozzle assembly, it is necessary to remove the assembly so that it can be held properly to avoid damaging it when removing the gas nozzle. On the top of the water-cooled nozzle assembly there are two spigots. The water passages run through these spigots and straight down the sides of the water-cooled nozzle. These passages cannot be seen from the outside of the water-cooled nozzle. If these water passages are squeezed with a wrench or vise they will cave in and cut off the water supply through the torch and to the torch’s water out & power cable. This will cause the torch to overheat; it will possibly cause severe damage to the torch and burn up the water out & power cable because cooling fluid will no longer be flowing through it.

When it is required that a wrench be used to grab the water-cooled nozzle, it is important to make sure that the jaws of the wrench are grabbing the water-cooled nozzle perpendicular to the water channels on sides of the water-cooled nozzle that are 90 degrees to the channels. This will avoid any pressure on the water passages and prevent them from caving in and restricting water flow.

In the factory, the water-cooled nozzles are placed in “soft jaws” in a vise that grab the water-cooled nozzle on the two sides 90 degrees to the water passages. This guarantees that the water-cooled nozzle will be grabbed correctly without damaging it, enabling the use of a wrench to remove the gas nozzle.

If the first two options are not available, the water-cooled nozzle can be placed in a lathe where the back collar is secured tightly with a chuck. The machine can be used to back out the gas cup. Whenever a gas nozzle is removed to be cleaned or replaced, the threads of the chrome water-cooled nozzle should be inspected and cleaned as well, and chased with a nozzle thread chaser tap if necessary. Forcing the gas nozzle back onto the water-cooled nozzle will cause the threads to gall. If this does happen, or if the threads become damaged in any other way, they can be re-tapped with the nozzle thread chaser tap, and a new gas nozzle should be applied.

For cleaning of threads, and re-tapping & cleaning damaged threads, D/F manufactures its own line of nozzle thread chaser taps which can be found here.