BARREL MOUNTING OPTIONS

Typical modern torch setups utilize a unitized cable assembly with the gas, water, power and conduit combined into a single replaceable unit. When one cable goes bad the whole unit is replaced. This can be expensive. Also, this approach does not allow for a large enough inner power cable needed for necessary high amperages, and it is restricted in size by small passages for water, gas and wire. Water-cooling and gas coverage are both limited by the size restrictions.

D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer’s existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer’s utilities. The back includes industry standard 3/8” shanks to allow the customer to connect the water in and water out lines, and a 3/16” shank to connect the gas line. Along with these hoses, the customer must plug the a 4/0 power cable directly from the power source to the back of the Utility Station. This is how the D/F torches are powered, NOT with a power cable to the wire feeder; there can be no jumper cable from the drive roll to the Utility Station. The power must travel through the Utility Station and down to the torch via the Water Out & Power Cable, hence the name. It is most important to remove the 4/0 power cable from the lug of the wire feeder drive roll stand, strip the cable back roughly 2”, and insert the 4/0 power cable into the back of the D/F Utility Station. Finally, a short gas hose jumper is needed for control of the gas. Remove the small black 3/16” hose that connects from the solenoid to the feeder input inside the wire feeder. The jumper can be attached by removing the 3/16” hose from the solenoid, and attaching the 3/16” gas jumper hose to the solenoid and to the back of the D/F Utility Station’s 3/16” shank.

Due to the fact that every welding application is different because of size restrictions, access restrictions, positioning restrictions, etc., D/F manufactures barrels in two variations, remote mount and direct mount.

REMOTE MOUNT/ROBOTIC BARRELS

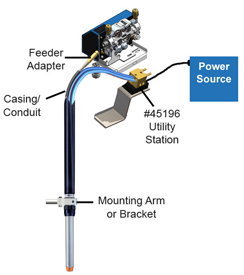

The D/F wire casing/conduit follows a different route than the water and gas lines. On remotely mounted guns and barrels, the casing/conduit comes

straight out the top of the barrel as the other hoses do (180 degrees), but attaches straight to the wire feeder with a feeder adapter. D/F refers to power pins

as feeder adapters, for on D/F barrel setups there is no power going to the wire feeder. The feeder adapters can hook up to any of the different Miller, Lincoln,

Esab, Welding Alloys, Fronius, Tweco, etc. wire feeders. In turn the D/F casing/conduit is not powered. Its only purpose is to support the liner, which protects

the casing and supports the wire.

The D/F wire casing/conduit follows a different route than the water and gas lines. On remotely mounted guns and barrels, the casing/conduit comes

straight out the top of the barrel as the other hoses do (180 degrees), but attaches straight to the wire feeder with a feeder adapter. D/F refers to power pins

as feeder adapters, for on D/F barrel setups there is no power going to the wire feeder. The feeder adapters can hook up to any of the different Miller, Lincoln,

Esab, Welding Alloys, Fronius, Tweco, etc. wire feeders. In turn the D/F casing/conduit is not powered. Its only purpose is to support the liner, which protects

the casing and supports the wire.

Remote mounting of a D/F torch requires a mounting bracket or robotic mounting arm to grab the torch. This arm or bracket is then mounted on a robot, fixture, gantry, x- y- z axis, or above a positioner or manipulator. The wire is brought into the torch through a conduit/casing (usually from 4ft15ft). Remote mounting enables customers to get the wire feeder away from the pre-heat, torch heat, and the work. It also allows the end user to access hard to reach areas. Furthermore, it allows for all of the utilities to be protected together inside a fire resistant sheath

The power cannot be placed on the wire feeder or drive roll stand, otherwise the casing/conduit will be “hot” and you will burn the casing/conduit off the torch. As you can see in the illustration, the 4/0 power cable goes directly from the power source to the D/F Utility Station (part #45196).

DIRECT MOUNT/AUTOMATIC BARRELS

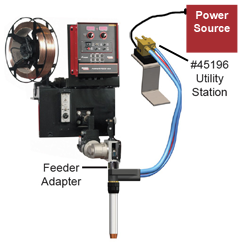

A directly mounted barrel plugs directly into the wire feeder. In a direct mount barrel the Water Out & Power Cable, water-in hose, gas hose come out of the

barrel at a 90 degree angle and go to the Utility Station, and there is no casing/conduit. The feeder adapter comes out the top of the barrel and connects directly

to the wire feeder.

A directly mounted barrel plugs directly into the wire feeder. In a direct mount barrel the Water Out & Power Cable, water-in hose, gas hose come out of the

barrel at a 90 degree angle and go to the Utility Station, and there is no casing/conduit. The feeder adapter comes out the top of the barrel and connects directly

to the wire feeder.

To directly connect a D/F torch to the wire feeder, simply thread the correct feeder adapter (Miller, Lincoln, ESAB) for the wire feeder into the top of the D/F torch and plug the torch directly into the wire feeder. The utilities leave the torch at a 90 degree angle, clearing the wire feeder, and can be connected to the utility station. As you can see in the illustration, the 4/0 power cable goes directly from the power source to the D/F Utility Station (part #45196).

DIRECT MOUNT BARREL - REMOTELY MOUNTED

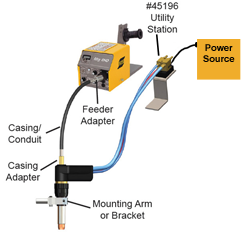

The Direct Mount torch, instead of being directly plugged into the wire feeder, is mounted away from the wire feeder, and requires a casing adapter to receive the conduit to run wire to the torch. This unique solution might work for jobs with very limited space. This is the preferred method when using external feeds such as adding carbide to the weld.

The Direct Mount torch, instead of being directly plugged into the wire feeder, is mounted away from the wire feeder, and requires a casing adapter to receive the conduit to run wire to the torch. This unique solution might work for jobs with very limited space. This is the preferred method when using external feeds such as adding carbide to the weld.

The power cannot be placed on the wire feeder or drive roll stand, otherwise the casing/conduit will be “hot” and you will burn the casing/conduit off the torch. As you can see in the illustration, the 4/0 power cable goes directly from the power source to the D/F Utility Station (part #45196).

These alternative setups utilizing the D/F Utility Station enable the D/F barrels to run cooler, work above 1000 degree pre-heat, increase the weld quality (X-ray quality welds), have increased durability, and run the full range of wire through 1/8”. It also allows for many different model options, saves on consumable costs, reduces down-time, and allows for a clean installation and ease in maintenance or replacement. The Utility Station is universal throughout the D/F product line. Every D/F barrel will hook up to the same Utility Station.