Air-Cooled MIG Guns - Direct Mount

External Shielding

Drawings Accessories

Overview

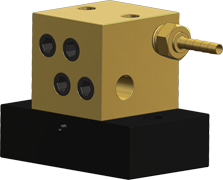

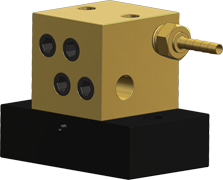

This air-cooled MIG machine torch with external shielding is readily adaptable to automatic welding. It is furnished completely assembled and ready for installation. The model has the feature of individual replaceable service connections to add to the durability and long life of the torch assemblies. The MAC-E - Machine, Air-Cooled Barrel is for slip-in tips, while the MAT-E - Machine, Air-Cooled Barrel is for threaded tips. Direct mounting is accomplished by an adapter to the wire drive, with shielding gas accommodated by a vertical external connection.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- High Speed, High Volume CO2 Welding

- 400 Amp CO2, 260 Amp Argon Current Capacity

- Power Cable Lug - Accepts 1/0 and 2/0 Power Cables

- Heavy Duty Brass Inner Body

- Chrome Plated Brass Front End - Reduced Spatter

- Quick-Disconnect External Gas Line

- Vertical Gas Height Adjustment - Reduced Spatter

Model Explanation

- MAC-E - Machine, Air-cooled, Collet Action (Slip-In Tip) - External Shielding

- MAT-E - Machine, Air-cooled, Threaded Current Tip - External Shielding

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|

| MAC-E, MAT-E | 400 amps CO2, 260 amps Argon |

2.3 lbs | .030"-1/16" Hard/Cored | 656MACE-MATE |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY |

|---|---|---|

| MAC-E, MAT-E | 8.625" | 1.250 |

Ordering Information

For Hard and Cored Wire

| DESCRIPTION | CODE NO. | ||||||

| Gun Only | 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | |

| MAC-E Slip-In Tip |

12735 MAC-E35 |

19660 MAC-E60 |

19661 MAC-E61 |

19662 MAC-E62 |

19663 MAC-E63 |

19664 MAC-E64 |

19665 MAC-E65 |

| MAT-E Threaded Tip |

12741 MAT-E41 |

19666 MAT-E66 |

19667 MAT-E67 |

19668 MAT-E68 |

19669 MAT-E69 |

19670 MAT-E70 |

19671 MAT-E71 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| MAC-E, MAT-E | 656MACE-MATE |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| Air-Cooled MIG Guns - External Shielding & Gasless One-Sheet |

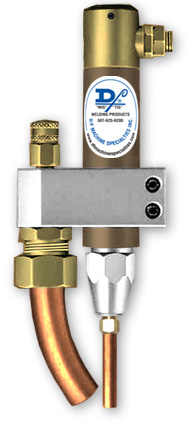

Utility Station #45184

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Air-Cooled MIG Guns - Remote Mount

Gasless

Drawings Accessories

Overview

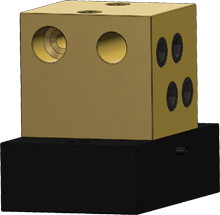

This open-arc gasless air-cooled MIG overlay cladding machine torch is readily adaptable to automatic welding. It is furnished completely assembled and ready for installation. This torch is ideal for single-head machines or multiple-head machines used with hardfacing and pipe forming applications. The model MAT-G - Machine, Air-Cooled, Threaded Tip has the feature of individual replaceable service connections to add to the durability and long life of the barrel assemblies. Direct mounting is accomplished by utilizing interconnections to the welding head or wire drive. Direct mounting is accomplished by an adapter to the wire drive.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- Up to 400 Amps

- Power Cable Lug - Accepts 1/0 and 2/0 Power Cables

- Heavy Duty Brass Inner Body

- Chrome Plated Brass Front End - Reduced Spatter

- High Temperature Insulation

Model Explanation

- MAC-G - Machine, Air-cooled, Collet Action (Slip-In Tip) - Gasless

- MAT-G - Machine, Air-cooled, Threaded Current Tip - Gasless

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|

| MAC-G, MAT-G | 400 amps CO2, 260 amps Argon |

1.1 lbs | .030"-1/16" Hard/Cored | 657 Gasless |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY |

|---|---|---|

| MAC-G, MAT-G | 6.625" | 1.250 |

Ordering Information

For Hard and Cored Wire

| DESCRIPTION | CODE NO. | ||||||

| Gun Only | 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | |

| MAC-G Slip-In Tip |

12743 MAC-G43 |

19680 MAC-G80 |

19681 MAC-G81 |

19682 MAC-G82 |

19683 MAC-G83 |

19684 MAC-G84 |

19685 MAC-G85 |

| MAT-G Threaded Tip |

12742 MAT-G42 |

19674 MAT-G74 |

19675 MAT-G75 |

19676 MAT-G76 |

19677 MAT-G77 |

19678 MAT-G78 |

19679 MAT-G79 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| MAC-G, MAT-G | 657 Gasless |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| Air-Cooled Curved MIG Guns One-Sheet |

Utility Station #45184

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.