W/C Curved 22° & 45° Machine Barrels

Drawings Accessories

Overview

The versatile Water-Cooled Machine Torch models NCC/LRN, HTC/LRN, NCC/N, & HTC/N can be used for a wide range of applications. The machine barrels may be applied to either a remote or direct mount Docking Spools®. With the various angles (22°, 35°, 45°, 60° and 90°) and lengths available (Long Reach 12.5" and Short 5"), a selection may be made to suit individual requirements.

The versatile D/F quick change Water-Cooled Automatic Torch models NCM/LRN, HTM/LRN, NCM/N, & HTM/N can be used for a wide range of automatic applications. With the various angles and lengths available, a selection may be made to suit individual automation requirements.

The composite modular design of the rugged, yet flexible, quick-disconnect model LRN (Long Reach 10" composite water-cooled nozzle) and the model N (short 5" composite water-cooled nozzle) torches allow the user to quickly change the swanneck (gooseneck) or cable assembly while maintaining tool center point, assuring accurate repeatability and continuous precision welding. These D/F automatic torches have a compact, stainless steel, water-cooled nozzle designed specifically to withstand unusually large amounts of reflected heat build-up and prolonged duty cycles. Water circulates internally through the docking spool to the nozzle and the tip, keeping the torches running cooler, and thus the torch and consumables last longer. Mounting is easy by directly plugging in the torch to any wire feeder with one of the many different wire feeder adapters. In the event that a component has to be adjusted or replaced, the docking spool makes this torch entirely serviceable and easy to repair or replace in seconds.

These welding assemblies are designated by torch models. The models NCM/LRN & NCM/N (slip-in contact tip) have a current capacity 500 amps in argon shielding. These accommodate slip-in current tips fastened by a collet action nut. The wire diameter range with hard wire is .030"-1/16", cored wire .035"-1/8", and aluminum wire range of .035"-3/32".

The torch models HTM/LRN & HTM/N (threaded contact tip) have a current capacity range of up to 650 amperes. Rating will be contingent on the combination of current tip and shielding gas to be used. The model HTM employs threaded CrZr (chromium zirconium copper) current tips and will accommodate .030" - 1/16" hard wire, .035" - 1/8" cored wire and 3/64" - 3/32" aluminum wires.

Standard assemblies have torch necks (water-cooled nozzles) that are either straight or bent at 22°, 35°, 45°, 60° or 90°, available in different lengths, and with cable assemblies and replacement docking spool bodies. The LRN & N series torches also share common consumables with the complete D/F product line.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. If you are currently having problems using the Tregaskiss Tough Gun I.C.E™ (Integrated Cooling Enhancer) because of high amperages, long duty cycles resulting in torches overheating, expensive gas diffusers, and short consumable life, this series of D/F Automatic Water-Cooled Torches is a superior alternative. There are no exterior water lines that can be damaged running down the outside of the torch. The D/F LRN torches are completely water-cooled throughout. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Features

- Quick-Change - Interchange Between Short, Long, Straight or Curved Goosenecks

- Fully Water-Cooled Internally - Gas Cup Recessed in Water Cooling

- Up to 500 Amps Continuous Duty Cycle

- Adaptable to Any Wire Feeder or Power Source

- Withstands Preheat Upwards of 900 Degrees

Model Explanation

- NCC-N - Normal Duty, Collet Action (Slip-In Tip), Curved - Short 5" Nozzle

- HTC-N - Heavy Duty, Threaded Tip, Curved - Short 5" Nozzle

- NCC-LRN - Normal Duty, Collet Action (Slip-In Tip), Curved - Long Rreach Nozzle

- HTC-LRN - Heavy Duty, Threaded Tip, Curved - Long Rreach Nozzle

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED |

RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| NCC-N | 400 amps | 4 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

541NB (All 22° & 45°) |

| HTC-N | 500 amps | 4 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN | 400 amps | 4.7 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| HTC-LRN | 500 amps | 4.7 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF W/C NOZZLE |

|---|---|---|

| NCC-LRN 22°, HTC-LRN 22° | 12.625" | 1.125" |

| NCC-N 22°, HTC-N 22° | 8.500" | 1.125" |

| NCC-LRN 45°, HTC-LRN 45° | 12.250" | 1.125" |

Ordering Information (Complete Assemblies)

| DESCRIPTION | CODE NO. | |

| COMPLETE ASSEMBLIES |

COMPLETE BARREL ONLY |

|

| NCC-N Curved 22° 5" | 40172 | 48227 |

| HTC-N Curved 22° 5" | 40187 | 48227 |

| NCC-LRN Curved 22° Long Reach | 40174NB | 48225NB |

| HTC-LRN Curved 22° Long Reach | 40189NB | 48225NB |

| NCC-LRN Curved 45° Long Reach | 40173NB | 48221NB |

| HTC-LRN Curved 45° Long Reach | 40188NB | 48221NB |

| Add Footage Digit to Item Code Number for Length Required. Example: Require 40174NB with 4 Ft. Utilities: 40174NB-4 | ||

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| NCC-LRN, HTC-LRN, NCC-N, HTC-N (All 22° & 45°) |

541NB |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| NCC-LRN 22° | 40172 | 40172 | 40172 |

| HTC-LRN 22° | 40187 | 40187 | 40187 |

| NCC-N 22° | 40174 | 40174 | 40174 |

| HTC-N 22° | 40189 | 40189 | 40189 |

| NCC-LRN 45° | 40173 | 40173 | 40173 |

| HTC-LRN 45° | 40188 | 40188 | 40188 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options |

Utility Station #45196

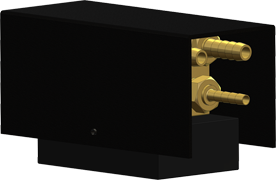

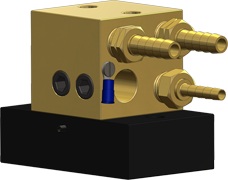

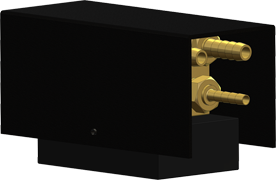

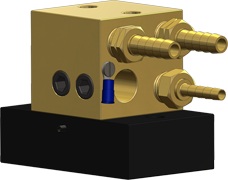

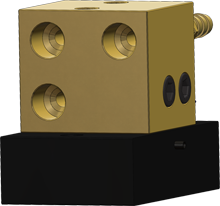

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Straight Short & LRN Machine Barrels

Drawings Accessories

Overview

The versatile MIG Water-Cooled Machine Barrel Models NCM/LRN - HTM/LRN can be used for a wide range of applications. The machine barrels may be applied to either a remote or direct mount Docking Spool®. With the various angles (22°, 35°, 45°, and 60°) and lengths available (Long Reach 12.5" and Short 5"), a selection may be made to suit individual requirements.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. If you are currently having problems using the Tregaskiss Tough Gun I.C.E™ (Integrated Cooling Enhancer) because of high amperages, long duty cycles resulting in torches overheating, expensive gas diffusers, and short consumable life, this series of D/F Automatic Water-Cooled Torches is a superior alternative. There are no exterior water lines that can be damaged running down the outside of the torch. The D/F LRN torches are completely water-cooled throughout. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- Quick-Change - Interchange Between Short, Long, Straight or Curved Goosenecks

- Fully Water-Cooled Internally - Gas Cup Recessed in Water Cooling

- Up to 500 Amps Continuous Duty Cycle

- Adaptable to Any Wire Feeder or Power Source

- Withstands Preheat Upwards of 900 Degrees

Model Explanation

- NCM-N - Normal Duty, Collet Action (Slip-In Tip), Machine Barrel - Short 5" Nozzle

- HTM-N - Heavy Duty, Threaded Tip, Machine Barrel - Short 5" Nozzle

- NCM-LRN - Normal Duty, Collet Action (Slip-In Tip), Machine Barrel - Long Rreach Nozzle

- HTM-LRN - Heavy Duty, Threaded Tip, Machine Barrel - Long Rreach Nozzle

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED |

RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| NCM-N | 400 amps | 4 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

541NB |

| HTM-N | 500 amps | 4 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCM-LRN | 400 amps | 4.7 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| HTM-LRN | 500 amps | 4.7 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF W/C NOZZLE |

|---|---|---|

| NCM-LRN, HTM-LRN | 12.625" | 1.125" |

| NCM-N, HTM-N | 9.250" | 1.125" |

Ordering Information

| DESCRIPTION | CODE NO. | |

| COMPLETE ASSEMBLIES |

COMPLETE BARREL ONLY |

|

| NCM-N Straight 5" | 40216 | 48240 |

| HTM-N Straight 5" | 40217 | 48240 |

| NCM-LRN Straight Long Reach | 40171 | 48121 |

| HTM-LRN Straight Long Reach | 40186 | 48121 |

| Add Footage Digit to Item Code Number for Length Required. Example: Require 40217 with 4 Ft. Utilities: 40217-4 | ||

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| NCM-N, HTM-N, NCM-LRN, HTM-LRN | 541NB |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| NCM-N | 40216 | 40216 | 40216 |

| HTC-N | 40217 | 40217 | 40217 |

| NCM-LRN | 40171 | 40171 | 40171 |

| HTM-LRN | 40186 | 40186 | 40186 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options |

Utility Station #45196

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.