Air-Cooled MIG Guns - Remote Mount

Drawings Accessories

Overview

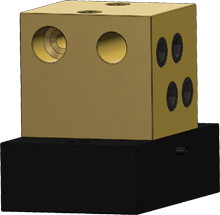

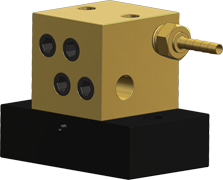

This air-cooled machine torch is readily adaptable to robotic welding. It is furnished completely assembled and ready for installation. Both the MAC - machine, air-cooled, slip-in tip and MAT - machine, air-cooled, threaded tip models have the feature of individual replaceable service connections to add to the durability and long life of the barrel assemblies. Remote mounting is accomplished by an insulated mounting bracket and utilizing a casing/conduit and an adapter to the wire drive. Shielding gas is accommodated by a vertical connection.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- 400 Amp CO2, 260 Amp Argon Current Capacity

- Power Cable Lug - Accepts 1/0 and 2/0 Power Cables

- Accommodates Robotic Welding Systems

- Several Nozzle Body Configurations Available

- Heavy Duty Brass Inner Body

- Chrome Plated Brass Front End

- Heavy Duty Copper Nozzle

- High Temperature Insulation

Model Explanation

- MAC - Machine, Air-cooled, Collet Action (Slip-In Tip)

- MAT - Machine, Air-cooled, Threaded Current Tip

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|

| MAC, MAT | 400 amps CO2, 260 amps Argon |

1.12 lbs | .030"-1/16" Hard/Cored | 653AM |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY |

|---|---|---|

| MAC, MAT | 8.625" | 1.250" |

Ordering Information

| DESCRIPTION | CODE NO. |

|---|---|

| MAC - Slip-In Tip | |

| MAC-17 - Nozzle Body 13176 | 12717 |

| MAT - Threaded Tip | |

| MAT-03 - Nozzle Body 13176 | 12703 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| MAC, MAT | 653AM |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| MAC-17 | 12717 | 12717 | 12717 |

| MAT-03 | 12703 | 12703 | 12703 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| Air-Cooled MIG Torches One-Sheet |

Utility Station #45184

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Air-Cooled MIG Guns - Remote Mount

Short Barrel

Drawings Accessories

Overview

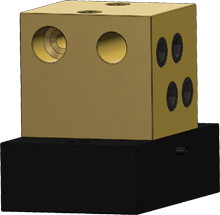

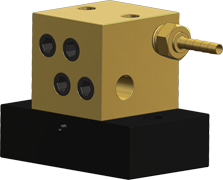

This air-cooled short machine torch is readily adaptable to robotic welding. It is furnished completely assembled and ready for installation. Both the MAC - machine, air-cooled, slip-in tip and MAT - machine, air-cooled, threaded tip models have the feature of individual replaceable service connections to add to the durability and long life of the barrel assemblies. Remote mounting is accomplished by an insulated mounting bracket and utilizing a casing/conduit and an adapter to the wire drive. Shielding gas is accommodated by a vertical connection.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- 400 Amp CO2, 260 Amp Argon Current Capacity

- Power Cable Lug - Accepts 1/0 and 2/0 Power Cables

- Accommodates Robotic Welding Systems

- Several Nozzle Body Configurations Available

- Heavy Duty Brass Inner Body

- Chrome Plated Brass Front End

- Heavy Duty Copper Nozzle

- High Temperature Insulation

Model Explanation

- MAC - Machine, Air-cooled, Collet Action (Slip-In Tip)

- MAT - Machine, Air-cooled, Threaded Current Tip

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|

| MAC, MAT | 400 amps CO2, 260 amps Argon |

1.10 lbs | .030"-1/16" Hard/Cored | 655AM |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY |

|---|---|---|

| MAC, MAT | 6.625" | 1.250" |

Ordering Information

| DESCRIPTION | CODE NO. |

|---|---|

| MAC - Slip-In Tip | |

| MAC-26 - Nozzle Body 13176 | 12726 |

| MAT - Threaded Tip | |

| MAT-24 - Nozzle Body 13176 | 12724 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| MAC, MAT | 655AM |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| MAC-17 | 12726 | 12726 | 12726 |

| MAT-03 | 12724 | 12724 | 12724 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| Air-Cooled MIG Torches One-Sheet |

Utility Station #45184

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

- D/F Machine Specialties® e-Newsletter

- D/F Machine Specialties® e-Newsletter

Sign up here to receive the High Current News® e-newsletter from D/F MACHINE SPECIALTIES®. This e-newsletter is packed full of information to keep you updated with the latest MIG & TIG welding news, product information and new updates from D/F!

You can unsubscribe at any time. Please refer to our Privacy Policy or Contact Us for more details.