W/C Tandem Machine Barrel

Drawings Accessories More Info

Overview

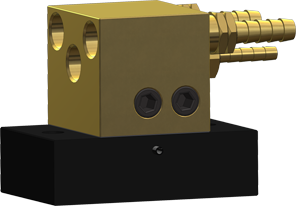

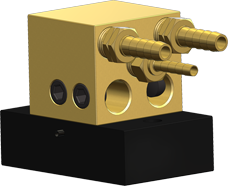

The D/F Machine Specialties specially designed high amperage MIG Tandem welding torch is a critical component of the MIG tandem welding system, engineered with specific spacing and alignment of adjustable two contact tips to achieve proper arc control. The torches are usually rated in terms of combined current flowing through both wires due to the demands of high amperage, high duty cycle production runs. The torch is rated at 1700 amps due to the fact that each isolated, water-cooled-to-the-tip inner body is capable of carrying 850 amps at 100% duty cycle. D/F's patented MIG Tandem Wire Torch has been developed for heavy-duty welding, where the requirements relating to heavy-duty applications and long welding times are rigorous. The D/F tandem wire welding torch is designed to provide excellent cooling of the nozzle, gas cup, body and the current tips. Two wire electrodes electrically insulated from one another must run through a common gas nozzle and share a common welding torch. Efficient cooling of the round shaped tandem gas cup prevents welding spatter easily sticking to the gas cup. The separate water-cooling of the nozzle reduces spatter and prolongs gas cup life. Because a lot of heat is generated in the tandem process it must be subsequently dissipated all the way to the front area of the contact tubes. Each body assembly is also separately water-cooled ensuring tip life and arc stability. The insulation of the two separate tandem torch inner bodies of the single common torch is done according to existing D/F standards, guaranteeing no electric flash-over between the two electric systems. The distance between the tandem contact tips (the wires) can vary by removing the body screws of one or both of the inner bodies. This allows rotation of each inner body increasing or decreasing the distance between the two welding wires. The D/F Tandem Barrel inner bodies can be either straight or bent to desired degrees to help achieve different center-point distances between the two tandem contact tips and are easily changeable.

Due to the fact that there are varying requirements for each tandem welding application, this series of D/F torches is tailored to fit each of these unique applications and falls under the "specialties", hence the name D/F Machine Specialties, and requires a 2-3 week delivery upon receipt of a purchase order. We highly recommend that customers also purchase a backup torch to reduce downtime due to the fact that these are custom torches and have a 2-3 week delivery upon receipt of order.

To provide maximum resistance to the abuses of day to day service, the tandem torch is of heavy duty construction with all metal parts well insulated from current carrying members. The compact in-line body allows the D/F Tandem Torch to be used in a variety of applications with ease of maneuverability and can access hard to reach areas of operation. To facilitate maneuverability, all service lines are internally connected to the tandem torch bodies and exit from the rear of the torch barrel. The tandem torch uses threaded (HTM) contact tips. The D/F Tandem Torch, like all D/F torches, is easily reparable, thus reducing downtime and increasing productivity.

The D/F Machine Specialties Tandem Water-Cooled MIG Machine Torch is configured to provide individual parameter control for each of two separate, and electrically isolated, welding arcs. This requires a pairing of all equipment; two specially designed high-speed inverter power sources, two wire drives, two separate welding wire pay-off sources and a D/F Tandem welding torch.

The D/F Machine Specialties Tandem Water-Cooled MIG Machine Torch can also be used as a Twin Wire Torch. When used as a MIG Twin Wire welding torch (two wires used with one power source), It can increase deposition rates by 20 to 30 percent versus single wire welding without significantly increasing heat input. The increase comes from the greater current density achieved by pushing a similar current over smaller, cross-sectional areas of wire.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- 1700 Amps Continuous Duty Cycle (850 Amps per Inner Body)

- Two (2) Independently Electrically Insulated Inner Bodies

- Two (2) Individually Adjustable Current Tips for Space and Alignment

- Water-Cooled Inner Bodies & Nozzle

- Large Frontal Area for Increased Gas Coverage

- Small Frontal Tapered Nozzle for Single Wire Applications

- Withstands Preheat & Extreme Conditions

- Adaptable to Any Wire Feeder or Power Source

Model Explanation

- HTM-TDP - Heavy Duty, Threaded Tip, Machine Barrel - Tandem Dual Power Cables

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED | RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| HTM-TDP | 1700 amps | 20 lbs | 6 quarts/min* | .035"-1/8" (.9m-3.2mm) | 1019 |

| *Based on 3 quarts/min for each of the 2 inner bodies | |||||

Barrel Dimensions

| MODEL | LENGTH | BODY DIAMETER |

|---|---|---|

| HTM-TDP | 14.5" | 2.750" |

Ordering Information

Complete Barrel Only

| DESCRIPTION | CODE NO. |

|---|---|

| HTM-TDP Tandem W/C Machine Barrel | 41301 |

Complete Assemblies

| DESCRIPTION | CODE NO. | |||||||

| 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | 10 Ft. | 12 Ft. | 15 Ft. | |

| HTM-TDP | 44706D-4 | 44706D-5 | 44706D-6 | 44706D-7 | 44706D-8 | 44706D-10 | 44706D-12 | 44706D-15 |

| Add Footage Digit to Item Code Number for Length Required. Example: Require 44706D with 3 Ft. Utilities: 44706D-3 |

||||||||

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| HTM-TDP | 1019 Tandem |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| HTM-TDP | 41301 | 41301 | 41301 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Choosing the Proper Chiller for Your Application |

|

| Torch Connection Options | |

| W/C Tandem Machine Barrel One-Sheet |

Utility Station #45188 - Dual Power Cable

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cables are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cables are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

More Info

The tandem process is a GMAW automated process that increases the application range of traditional single-wire GMAW processes: Two electrically isolated wire electrodes are positioned in line, in the direction of travel. The first electrode, the 'Lead' (Mode A), controls the majority of the base plate penetration. The second electrode, the 'Follow' (Mode B), controls weld bead appearance and contour, edge wetting, and adding to the overall deposit rate. The spacing between the two wires is usually less than 15mm so that both welding arcs are delivering to a common weld puddle, but can be adjusted for job requirements and different applications. The process uses a true tandem configuration of dual power sources and two wire feeders to generate two separate welding arcs. The output of the two power sources are coordinated by either a robot controller for robotic applications, or by a Tandem interface for dedicated hard automated work cells. The two arcs are positioned to operate in a common weld puddle by a specially designed high amperage D/F Machine Specialties patented Tandem Water-Cooled "MIG" welding torch. Operation of the welding arcs in the close proximity of a common weld puddle is made possible by the use of high-speed dual power source output coordinating the interaction of the welding arcs. This unique operating arrangement promotes productivity, often greater than two separate wire electrodes, while providing the operating convenience of a single torch process.

The tandem process establishes a means for increasing both the travel speed and deposition rate without compromising the weld quality. The ability of the process to control heat input and bead wetting further enhances weld quality and minimizes weld repair associated with burn-through on thin components, or distortion on thick members. The process works best with a large diameter 'Lead' (Mode A) wire and a small diameter 'Follow' (Mode B) wire. The larger 'Lead' wire may represent as much as 65% of the total deposition rate, while providing greater penetration. The smaller, trail welding wire is focused on the trail edge of the weld puddle. The trail wire is typically smaller in diameter and therefore draws less current. This helps to control the shared weld puddle and aids in keeping it cool. A common compromise is to specify the 'Lead' and 'Follow' welding wires to be the same diameter to satisfy inventory constraints or because the direction of welding must be reversed somewhere on the weldment.

The Most Common Variants of the Tandem Process:

- Pulsed/Standard mode: 'Lead' (Mode A) arc is synchronized pulsed while the 'Follow' (Mode B) arc is Constant Voltage for achieving maximum welding speed and gap bridging.

- Standard/Pulsed mode: Best for deep penetration the 'Lead' (Mode A) arc is in Constant Voltage mode which maximizes penetration and travel speed while the 'Follow' (Mode B) arc is in pulse mode to reduce heat input and cool the weld puddle.

- Standard/Standard mode: 'Lead' (Mode A) and 'Follow' (Mode B) arcs are both in Constant Voltage mode usually for welding with just one electrode and switching to the other when changing directions to reduce cycle time.

Benefits:

- Pulsed/Standard mode: 'Lead' (Mode A) arc is synchronized pulsed while the 'Follow' (Mode B) arc is Constant Voltage for achieving maximum welding speed and gap bridging.

- Standard/Pulsed mode: Best for deep penetration the 'Lead' (Mode A) arc is in Constant Voltage mode which maximizes penetration and travel speed while the 'Follow' (Mode B) arc is in pulse mode to reduce heat input and cool the weld puddle.

- Direction of process is independent

- Have capability to track in either direction with either wire ('Lead' or 'Follow') for maximum flexibility with creating programs and doing off-line programming.

- Allows full advantage of robots working range.

- Capable of tracking off either wire

- Lowers production costs

- Increases productivity

Advantages:

- High welding speeds

- Faster cycle times

- Reduced heat input

- Resists burn-through on thin materials

- Low spatter levels

- Good penetration on thick materials

Typical Applications:

The tandem process is typically used on cylinders, tanks, water heaters, lawn and garden equipment, gussets and stiffeners, off-road equipment, construction equipment and agricultural machinery, ASME tanks, joggle joints, and pipe and tubular components.

Power Sources:

Tandem-Wire welding made substantial advances when power sources were converted to digital technology. Now it was possible to control the welding process in a completely digital manner, which yielded considerable benefits:

- Small and compact electronics.

- Flexible system control of the welding arc

- Long term stability not affected by temperature drifts

It was vital that the two power sources communicate with each other for the synchronization of the two electric arcs. An additional requirement was that the robot could activate the two power sources as a single power source.

Wire Feeders:

Advancing two welding wire electrodes requires two wire feeder mechanisms that each advance one electrode. In the automated process it's important that the wire feeders are capable of unwinding wire from large drum coils in a manner that also straightens the wire.

In conclusion, for all applications a substantial increase in productivity can be obtained. The rule of thumb sometimes mentioned, "double-wire = double speed", appears to be correct compared with conventional single-wire welding. The welding speed, the weld quality and the process tolerances must however be balanced (evaluated for each case). It is also interesting to note that the tandem welding process has a much higher penetration capacity than single-wire welding. D/F's Tandem torch, will help reach maximum output of the welding process by increased weld speeds, increased arc stability for optimum weld quality and consistency, higher deposition, and Maximum number of hours of welding contact/current tip life, thus reducing shut downs and start ups also reducing the amount of scrap produced.