Water-Cooled Robotic TIG Torch

Drawings Accessories

Overview

The Water-Cooled Kel-Melt (KMF) TIG Torch is intended for use with a Kel-Melt Sample Re-Melt Furnace. This heavy duty Water-Cooled TIG Torch is specific to this machine application and the tungsten inert arc process. The torch accommodates a tungsten range of .040"-1/4" with a tubular single collet design providing clamping pressure. Due to the fact that there are varying requirements for each TIG welding application, this series of D/F torches is tailored to fit each of these unique applications and falls under the "specialties", hence the name D/F Machine Specialties, and requires a 2-3 week delivery upon receipt of a purchase order. We highly recommend that customers also purchase a backup torch to reduce downtime due to the fact that these are custom torches and have a 2-3 week delivery upon receipt of order.

The Kel-Melt Sample Re-Melt Furnace is for the rapid melting of small sample chips into a button suitable for spectrograph analysis. The Kel-Melt Furnace by Zeebac, Inc. has evolved from a unit originally built by John Kelly. Metal drillings, chips, wire, etc. can be placed in the water-cooled copper crucible, and after rapid melting with a high D.C. current, under argon, form a sample button for spectrograph analysis. Tests have shown exceptional reproducibility between buttons of the same material with very minimal losses of the alloying elements. The D/F Machine Specialties KMF TIG Torch has improved water-cooling for up to 500 amps and a copper single collet for improved conductivity and heat-dissipating qualities.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Features

- Replacement for Kel-Melt Furnace TIG Torch

Model Explanation

- KMF - Kel-Melt Furnace TIG Torch

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED | RECOMMENDED TUNGSTEN ELECTRODE RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| KMF | 500 amps | 1.2 lbs | 3 quarts/min | .040"-1/4" | KMF TIG Barrel |

Barrel Dimensions

| MODEL | OVERALL LENGTH | HEAT SHIELD DISC DIAMETER |

BODY DIAMETER |

|---|---|---|---|

| KMF | 6" | 2" | 1" |

Ordering Information

Complete Assemblies

| DESCRIPTION | CODE NO. |

|---|---|

| Kel-Melt KMF TIG Torch | 30406-4 |

| Add Footage Digit to Item Code Number for Length Required. Example: Require 30406 with 4 Ft. Utilities: 30406-4 | |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| KMF | KMF |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options |

Utility Station #45196

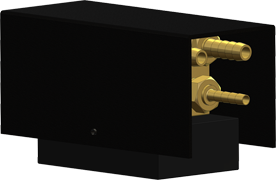

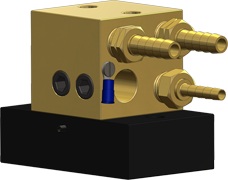

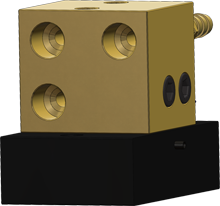

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.