34111 Cold Wire Feed Attachment

Overview

The TIG Cold Wire Feed process is suited for automated and manual TIG welding applications. The system will accurately feed 0.030” through 1/8” (0.9 to 3.2 mm) hard and soft wires for mechanized TIG or plasma welding. Cold Wire Feeders use standard "spooled" wire for longer arc time, and eliminates stub loss associated with 36" (914mm) cut length welding rod for an increase in productivity. The welding speed is increased and filler metal is fed precisely and evenly to the weld pool. This allows even less-experienced welders to achieve outstanding results.

The D/F Cold Wire Feed Head will accommodate the Collet Action Slip-in Current Tip for quick and easy insertion and removal of the Cold Wire Feed Copper Tip. It can be used with the ¼” slip in tips for smaller sizes of wire, or the 5/16” slip in tips for larger wires. The casing and liner (purchased separately) is secured by a simple set screw allowing the user to either lock the casing in place or loosen it just a little so that it can rotate. Our wire casings are designed with a flexible polymer core for flexibility, or with a steel-reinforced piano-wound core for extra support and smooth feeding. You can insert D/F's full line of nylon liners for aluminum and inconel welding and steel-wound liners for hard/cored/stainless welding. We offer the heaviest-duty liner system available with superior durability and feedability for extreme duty cycles. They are available in pre-cut lengths of 2 ft to 15 ft (61cm to 4.6m). They are tested and proven to have the lowest friction in the industry and have a standard spatter resistant outer jacket.

We can make any length casing (conduit, whip), in any quantity, for wires of .030", .035", .045", .052", 1/16", 3/64", 5/64", 3/32", 1/8" and other diameters .9mm – 3.2mm). Please contact the factory with your needs for a quote.

For a complete Cold Wire TIG System, you need both the Cold Wire Feeder and a TIG torch with cold wire TIG capabilities. The Cold Wire TIG System works independently of a standard TIG power supply using normal TIG welding parameters. The TIG process is very good for automation purposes and applications with robots. As the welding power is not coupled to the wire feed, the deposition rate can be controlled independently from the electrical power and thus perfectly adapted to the welding task. In the case of an automatic supply a distinction is made between hot wire feeding and cold wire feeding. When feeding cold wire, the filler material is led to the welding spot without current and molten in the arc of the main process. The TIG process creates very high-quality, spatter-free weld seams.

The D/F Cold Wire Feed unit can connect to any Lincoln, Miller, ESAB, Jetline, Cloos, Fronius, or CK "CWM" series machines and wire feeders.

TIG/GTAW Cold Wire Feed Benefits:

- High-grade, spatter-free weld quality

- Avoidance of extensive reworks

- No filler material

- Automates adding of filler metal in TIG Welding

- All weld parameters can be duplicated

- Works with 2 roll or 4 roll feeders, accepts multiple wire sizes

- Eliminates TIG rod stub loss

- Makes fully automatic machine TIG welding possible

- Results are consistent and high-quality welds

- Thin to thick materials

- Manual and automated welding

Ordering Information

Complete Assembly

| DESCRIPTION | CODE NO. |

|---|---|

| Cold Wire TIG Assembly (Must Specify Wire Size) |

34111 |

Water-Cooled Robotic TIG Torch

Drawings Accessories More Info

Overview

The TM500-B TIG Bottom Load Machine Barrel incorporates the same design as previously described (TM500) but is a bottom load type barrel for robotic applications. Tungsten electrodes are fastened by a collet action nut. A unique feature of this water-cooled TIG barrel is that the nozzle assembly water chamber and inner body water chamber are serially connected to each other, thus completely eliminating the need for gaskets or o-rings in the water passage system. Maximum current rating with thoriated tungsten electrodes is 500 amperes DC straight polarity, and 300 amperes AC. High frequency may be superimposed over standard current on a continuous or intermittent basis. There are five (5) collets available for use with this machine barrel with sizes of .040”, 1/16”, 3/32”, 1/8”, and 5/32”. The singular collet design provides clamping pressure when the collet is securely fastened on the tungsten.

The TM500-B TIG Bottom Load Machine Barrel incorporates the same design as previously described (TM500) but is a bottom load type barrel for robotic applications. Tungsten electrodes are fastened by a collet action nut. A unique feature of this water-cooled TIG barrel is that the nozzle assembly water chamber and inner body water chamber are serially connected to each other, thus completely eliminating the need for gaskets or o-rings in the water passage system. Maximum current rating with thoriated tungsten electrodes is 500 amperes DC straight polarity, and 300 amperes AC. High frequency may be superimposed over standard current on a continuous or intermittent basis. There are five (5) collets available for use with this machine barrel with sizes of .040”, 1/16”, 3/32”, 1/8”, and 5/32”. The singular collet design provides clamping pressure when the collet is securely fastened on the tungsten.

The TM500-B Machine Torch Series features a heavy-duty 500 amp water-cooled power cable. This water-cooled automated TIG barrel has the unique feature of the nozzle assembly water passages being serially connected to the inner body water chamber by means of sliding removable connectors. This allows ease of maintenance and eliminates the use of o-rings or gaskets in the water passage system.

D/F Nozzles (also called gas cups) provide a given amount of shielding gas coverage to the weld pool, according to their size (anywhere from 1/4- to 5/8-inch ID). For example, a smaller nozzle provides less gas coverage than a larger one. Nozzles also vary in price and performance. Built-in gas lens/gas difusser improves gas coverage to eliminate shielding gas turbulence and improve weld quality (all models). The TM500-B Front Load TIG Torch is available in 10.25" barrel lengths to meet exact welding requirements on precise mechanized jobs. Front tungsten loading/tightening eases tungsten changeover and extension adjustments.

The most cost effective are 90 or 95 percent alumina oxide nozzles, which work adequately for lower amperage applications. These nozzles, however, do not resist thermal shock on higher amperage applications very well and tend to deteriorate or crack and fall off.

Lava nozzles cost more than alumina oxide nozzles and are more resistant to cracking. These nozzles work well on medium to high amperage applications.

The bottom line when choosing TIG consumables is to look for factory OEM parts that provide you with the durability and performance you need. A wide variety of options exist for back caps, collets and collet bodies, gas lenses and nozzles, all of which offer distinct advantages, disadvantages and cost considerations. For less critical applications, the less expensive alumina nozzles provide adequate performance. However, if you need high performance, it is well worth your while to purchase more expensive, long-lasting lava nozzles or cups. Doing so minimizes the chance of consumable failures that could ultimately increase the cost for rework associated with weld inconsistencies.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Features

- Water-Cooled Inner Body & Nozzle

- 500 Amp Bottom Load

- Adaptable to Any Power Source & Robotic Application

- Withstands Preheat & Extreme Conditions

Model Explanation

- TM500-B - Tungsten Machine Barrel, 500 Amp - Bottom Load Tungsten

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED | RECOMMENDED TUNGSTEN ELECTRODE RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| TM500-B | 500 amps | 2.5 lbs | 3 quarts/min | .040"-5/32" (1mm-4mm) | 66TMB |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY HOUSING |

|---|---|---|

| TM500-B | 10.25" | 1.625" |

Ordering Information

Complete Assemblies

| DESCRIPTION | CODE NO. | ||||||||

| 2 Ft. | 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 8 Ft. | 10 Ft. | 12 Ft. | 15 Ft. | |

| TM500-B | 15237 TM502-B |

15238 TM503-B |

15239 TM504-B |

15240 TM505-B |

15241 TM506-B |

15242 TM508-B |

15243 TM510-B |

15244 TM512-B |

15245 TM515-B |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| TM500-B | 66TMB |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| TM500-B | 15239 | 15239 | 15239 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| W/C TIG Machine Barrel One-Sheet |

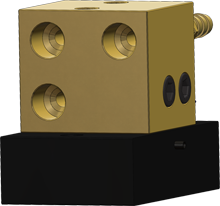

Utility Station #45196

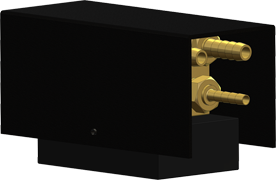

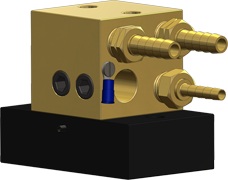

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Consumables

Tungsten Collet Sizes

| DESCRIPTION | CODE NO. | ||||

| .040" (1mm) |

1/16" (1.6mm) |

3/32" (2.4mm) |

1/8" (3.2mm) |

5/32" (4mm) |

|

| Collet for Tungsten | 19272 | 19273 | 19274 | 19275 | 18158 |

TIG Gas Nozzle Sizes

| DESCRIPTION | CODE NO. | |||

| 1/4" (No. 4) |

3/8" (No. 6) |

1/2" (No. 8) |

5/8" (No. 10) |

|

| Ceramic Gas Nozzle | 15895 | 15896 | 15897 | 15898 |

Subcategories

- D/F Machine Specialties® e-Newsletter

- D/F Machine Specialties® e-Newsletter

Sign up here to receive the High Current News® e-newsletter from D/F MACHINE SPECIALTIES®. This e-newsletter is packed full of information to keep you updated with the latest MIG & TIG welding news, product information and new updates from D/F!

You can unsubscribe at any time. Please refer to our Privacy Policy or Contact Us for more details.