Water-Cooled Robotic TIG Torch

Drawings Accessories

Overview

The Water-Cooled Kel-Melt (KMF) TIG Torch is intended for use with a Kel-Melt Sample Re-Melt Furnace. This heavy duty Water-Cooled TIG Torch is specific to this machine application and the tungsten inert arc process. The torch accommodates a tungsten range of .040"-1/4" with a tubular single collet design providing clamping pressure. Due to the fact that there are varying requirements for each TIG welding application, this series of D/F torches is tailored to fit each of these unique applications and falls under the "specialties", hence the name D/F Machine Specialties, and requires a 2-3 week delivery upon receipt of a purchase order. We highly recommend that customers also purchase a backup torch to reduce downtime due to the fact that these are custom torches and have a 2-3 week delivery upon receipt of order.

The Kel-Melt Sample Re-Melt Furnace is for the rapid melting of small sample chips into a button suitable for spectrograph analysis. The Kel-Melt Furnace by Zeebac, Inc. has evolved from a unit originally built by John Kelly. Metal drillings, chips, wire, etc. can be placed in the water-cooled copper crucible, and after rapid melting with a high D.C. current, under argon, form a sample button for spectrograph analysis. Tests have shown exceptional reproducibility between buttons of the same material with very minimal losses of the alloying elements. The D/F Machine Specialties KMF TIG Torch has improved water-cooling for up to 500 amps and a copper single collet for improved conductivity and heat-dissipating qualities.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Features

- Replacement for Kel-Melt Furnace TIG Torch

Model Explanation

- KMF - Kel-Melt Furnace TIG Torch

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED | RECOMMENDED TUNGSTEN ELECTRODE RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| KMF | 500 amps | 1.2 lbs | 3 quarts/min | .040"-1/4" | KMF TIG Barrel |

Barrel Dimensions

| MODEL | OVERALL LENGTH | HEAT SHIELD DISC DIAMETER |

BODY DIAMETER |

|---|---|---|---|

| KMF | 6" | 2" | 1" |

Ordering Information

Complete Assemblies

| DESCRIPTION | CODE NO. |

|---|---|

| Kel-Melt KMF TIG Torch | 30406-4 |

| Add Footage Digit to Item Code Number for Length Required. Example: Require 30406 with 4 Ft. Utilities: 30406-4 | |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| KMF | KMF |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options |

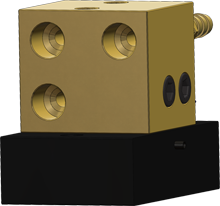

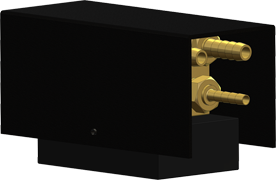

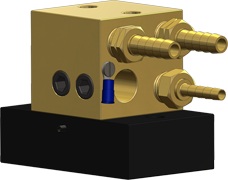

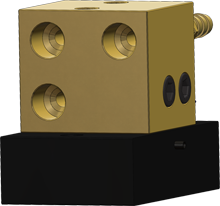

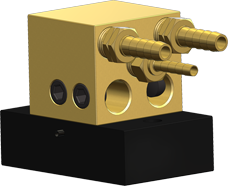

Utility Station #45196

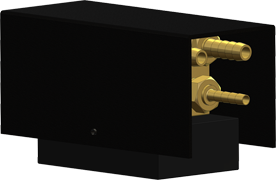

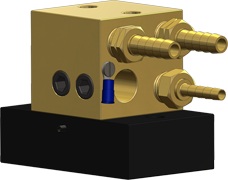

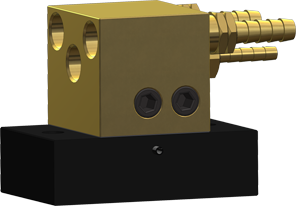

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Water-Cooled Automatic TIG Torch

Ceramic Gas Nozzle

Drawings Accessories More Info

Overview

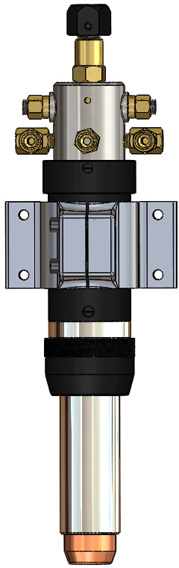

D/F Machine Specialties machine-held water-cooled TIG torches or GTAW torches are designed to meet the stringent and continuous demands of precise, high-amperage mechanized welding applications. The D/F Machine Specialties TM500-CN (Tube Mill) Top Load TIG Automated Machine Barrel is intended for semi-automatic or automatic machine applications of the tungsten inert arc process. The barrel accommodates top load of tungsten with a tubular dual collet design providing clamping pressure at two points.

The TM 500 Machine Torch Series features a heavy-duty 500 amp water-cooled power cable. This water-cooled automated TIG barrel has the unique feature of the nozzle assembly water passages being serially connected to the inner body water chamber by means of sliding removable connectors. This allows ease of maintenance and eliminates the use of o-rings or gaskets in the water passage system.

D/F Nozzles (also called gas cups) provide a given amount of shielding gas coverage to the weld pool, according to their size (anywhere from 1/4- to 5/8-inch ID). For example, a smaller nozzle provides less gas coverage than a larger one. Nozzles also vary in price and performance. Built-in gas lens/gas difusser improves gas coverage to eliminate shielding gas turbulence and improve weld quality (all models). The TM 500 Back Load TIG Torch is available in 12.5" barrel lengths to meet exact welding requirements on precise mechanized jobs. Front or back tungsten loading/tightening eases tungsten changeover and extension adjustments (all models). Internal tungsten adjustment eases fine positioning of tungsten and allows for axial movement of 1/4 inch (all models).

The most cost effective are 90 or 95 percent alumina oxide nozzles, which work adequately for lower amperage applications. These nozzles, however, do not resist thermal shock on higher amperage applications very well and tend to deteriorate or crack and fall off.

Lava nozzles cost more than alumina oxide nozzles and are more resistant to cracking. These nozzles work well on medium to high amperage applications.

The bottom line when choosing TIG consumables is to look for factory OEM parts that provide you with the durability and performance you need. A wide variety of options exist for back caps, collets and collet bodies, gas lenses and nozzles, all of which offer distinct advantages, disadvantages and cost considerations. For less critical applications, the less expensive alumina nozzles provide adequate performance. However, if you need high performance, it is well worth your while to purchase more expensive, long-lasting lava nozzles or cups. Doing so minimizes the chance of consumable failures that could ultimately increase the cost for rework associated with weld inconsistencies.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Features

- Water-Cooled Inner Body & Nozzle

- 500 Amp Top Load

- Adaptable to Any Power Source & Robotic Application

- Withstands Preheat & Extreme Conditions

- Dual Clamping Collet Provides Pressure at Two Points

- Tungsten Range .040"-5/32" (1mm-4mm)

- Gas Cup Range 1/4"-5/8" (#4-#10, 6.5mm-16mm)

Model Explanation

- TM500-CN - Tungsten Machine Barrel, 500 Amp - Ceramic Nozzle

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED | RECOMMENDED TUNGSTEN ELECTRODE RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| TM500-CN | 500 amps | 2.5 lbs | 3 quarts/min | .040"-5/32" (1mm-4mm) | 64TM |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY HOUSING |

|---|---|---|

| TM500-CN | 12.5" | 1.625" |

Ordering Information

Complete Barrel Only

| DESCRIPTION | CODE NO. |

|---|---|

| TM500 | 15499 |

Complete Assemblies

| DESCRIPTION | CODE NO. | |||||||||

| 2 Ft. | 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | 10 Ft. | 12 Ft. | 15 Ft. | |

| TM500 | 15192 TM502 |

15193 TM503 |

15194 TM504 |

15195 TM505 |

15196 TM506 |

15197 TM506 |

15198 TM508 |

15199 TM510 |

15200 TM512 |

15201 TM515 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| TM500-CN | 64TM |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| TM500-CN | 15499 | 15499 | 15499 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| W/C TIG Machine Barrel One-Sheet |

Utility Station #45196

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Consumables

Tungsten Collet Sizes

| DESCRIPTION | CODE NO. | ||||

| .040" (1mm) |

1/16" (1.6mm) |

3/32" (2.4mm) |

1/8" (3.2mm) |

5/32" (4mm) |

|

| Collet for Tungsten | 15871 | 15872 | 15873 | 15874 | 15875 |

TIG Gas Nozzle Sizes

| DESCRIPTION | CODE NO. | |||

| 1/4" (No. 4) |

3/8" (No. 6) |

1/2" (No. 8) |

5/8" (No. 10) |

|

| Ceramic Gas Nozzle | 15895 | 15896 | 15897 | 15898 |

Water-Cooled Robotic BIG TIG® Torch

Water-Cooled Robotic BIG TIG® Torch with 14086 Mounting Bracket

Drawings Accessories More Info

Overview

The “BIG TIG®” 1000 Amp High Current Machine Barrel is recommended for mechanized welding applications where production demands the maximum durability and quality for mechanized gas tungsten arc welding. The model TM1000 as provided will accommodate tungsten sizes of 1/8" (3.2mm), 5/32" (4mm), 3/16" (4.8mm), 1/4" (6.5mm), 5/16" (8mm), and 3/8" (9.5mm). The water-cooled nozzle accepts threaded gas nozzles ranging from 11/16"” through 1-1/4” inner diameter. Maximum current capacity applicable to the model TM1000 is 1000 amperes. Mounting is accomplished by using the D/F #14086 Mounting Bracket.

Features

- 1000 Amps Current Capacity

- Large Tungsten Diameters: 1/8"-.375" (3.2mm-9.5mm)

- Extreme Conditions & Duty Cycles

- Water-Cooled Inner Body & Nozzle

Model Explanation

- TM1000 - Tube Mill, 1000 Amp

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED | RECOMMENDED TUNGSTEN ELECTRODE RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| TM1000 | 1000 amps | 11.8 lbs | 1 gallon/min | 1/8"-.375" (3.2mm-9.5mm) | 63TM |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY HOUSING |

|---|---|---|

| TM1000 | 19" | 2.750" |

Ordering Information

Complete Barrel Only

| DESCRIPTION | CODE NO. |

|---|---|

| TM1000 | 15505 |

Complete Assemblies

| DESCRIPTION | CODE NO. | |||||||||

| 2 Ft. | 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | 10 Ft. | 12 Ft. | 15 Ft. | |

| TM1000 | 15202 | 15203 | 15204 | 15205 | 15206 | 15207 | 15208 | 15210 | 15212 | 15215 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| TM1000 | 63TM |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| TM1000 | 15505 | 15505 | 15505 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| W/C BIG TIG® Machine Barrel One-Sheet |

Utility Station #45188 - Dual Power Cable

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cables are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cables are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

More Information

The D/F "BIG TIG®" Tube Mill 1000 (TM1000) Water-Cooled TIG Torch will help reach maximum output of the tube mill with increased tube mill weld speeds, increased arc stability for optimum weld quality and consistency, and maximized number of hours for welding electrode tip life, thus reducing mill shut downs and start ups, and also reducing the amount of scrap produced. The "BIG TIG®" 1000 amp high current machine barrel is ideal for Mechanized or Robotic pipe/roll forming welding applications. Due to the fact that there are varying requirements for each TIG welding application, this series of D/F torches is tailored to fit each of these unique applications and falls under the "specialties", hence the name D/F Machine Specialties®, and requires a 2-3 week delivery upon receipt of a purchase order. We highly recommend that customers also purchase a backup torch to reduce downtime due to the fact that these are custom torches and have a 2-3 week delivery upon receipt of order.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties® does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

D/F Machine Specialties® has been committed to producing the finest American made welding products available on the market today. D/F's MIG (Gas Metal Arc Welding) & TIG (Gas Tungsten Arc Welding) torches have been used exclusively with welding automation equipment by Lincoln Electric, Miller Electric, Linde/ESAB, and Thermadyne for over 40 years. For automated welding systems, hard automation, high deposition, high current density, and large wire diameters that require preheat and high amperage, a D/F heavy duty water-cooled weld automation torch is ideal and has been used for large diameter aluminum welding, metal build up, hardbanding, hardfacing, metal spray applications, and pipeline construction, or even retrofit with a flux delivery system for sub-arc applications, and applications where carbide is added like with the Welding Alloys Multi Surfacer: custom designed automated welding equipment. Our torches have been designed, tested, used and continuously upgraded for more than 40 years, in almost every type of environment. The flexibility of D/F Machine Specialties® automatic welding torches makes them ideal for all fabrication applications. Our torches are suitable for GMAW, pulsed GMAW and FCAW processes. They provide a wide range of travel, wire feed, and oscillation parameters to accommodate various materials, thicknesses and joint designs.

The most cost effective are 90 or 95 percent alumina oxide nozzles, which work adequately for lower amperage applications. These nozzles, however, do not resist thermal shock on higher amperage applications very well and tend to deteriorate or crack and fall off.

Consumables

Tungsten Collet Sizes

| DESCRIPTION | CODE NO. | |||||

| 1/8" (3.2mm) |

5/32" (4mm) |

3/16" (4.8mm) |

1/4" (6.5mm) |

5/16" (8mm) |

3/8" (9mm) |

|

| Collet for Tungsten | 15804 | 15805 | 15806 | 15807 | 15808 | 15809 |

- D/F Machine Specialties® e-Newsletter

- D/F Machine Specialties® e-Newsletter

Sign up here to receive the High Current News® e-newsletter from D/F MACHINE SPECIALTIES®. This e-newsletter is packed full of information to keep you updated with the latest MIG & TIG welding news, product information and new updates from D/F!

You can unsubscribe at any time. Please refer to our Privacy Policy or Contact Us for more details.