Air-Cooled 35° Curved Gun

Drawings Accessories More Info

Overview

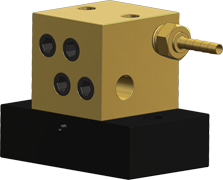

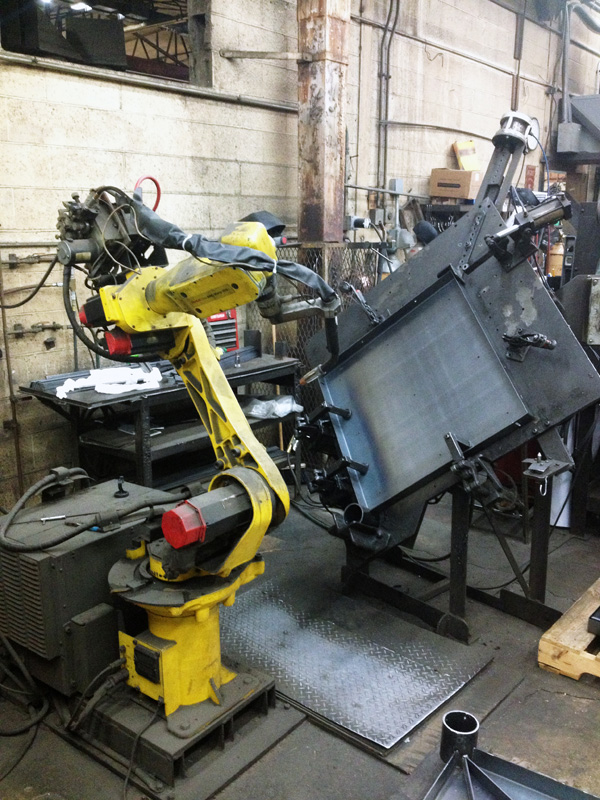

The rugged Cobot, Robotic and Automativ air-cooled CA-C/CA-T Series 400 35, 45, 55 degree curved welding guns come pre-assembled and ready to install. They feature individual replaceable service connections with a removable cable hose sheath to add to the durability and long life of these gun assemblies. The Air-Cooled CA-C CA-T Series 400 Machine Barrels are readily adaptable to mechanized or robotic welding. The models are furnished completely assembled and ready for installation. Both models have the feature of individual replaceable service connections with a removable cable/hose sheath to add to the durability and long life of the barrel assemblies. Remote mounting is accomplished by an insulated mounting bracket and utilizing a casing/conduit and an adapter to the wire drive. Throughout the years, Vectis Automation and Universal Robots with their Cobot Robotic welding cells. Lincoln Electric has also used D/F Machine Specialties MIG and TIG torches exclusively on FANUC robots. The typical robotic cell included the Fanuc ArcMate 100 robot models and the Lincoln Powerwave 450 power supply.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Contact Vectis Automation, LLC to discuss your unique COBOT application.

Phone: 970-852-5200

Email:

Features

- 400 Amp Current Capacity

- 1/0 Power Cable

- Accommodates Robotic Welding Systems

- Several Nozzle Body Configurations Available

- Heavy Duty Brass Inner Body

- Chrome Plated Brass Front End

- Heavy Duty Copper Nozzle

- High Temperature Insulation

Model Explanation

- CA-C - Curved, Air-cooled, Collet Action (Slip-In Tip)

- CA-T - Curved, Air-cooled, Threaded Current Tip

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|

| CA-C, CA-T | 400 amps CO2, 260 amps Argon |

1.8 lbs | .030"-1/16" Hard/Cored, 3/64"-1/16" AL |

435 CA-C CA-T |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BARREL HOUSING | DIAMETER OF NOZZLE BODY | NOZZLE TO BODY TUBE CLEARANCE |

|---|---|---|---|---|

| 35° CA-C, CA-T | 14.375" | 1.450" | 1.0625" | 5.375" |

Ordering Information

For Hard and Cored Wire

| DESCRIPTION | CODE NO. | ||||||||

| 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | 10 Ft. | 12 Ft. | 15 Ft. | |

| Model CA-C/CA-T w/ Nozzle Body 13197 |

17840 | 17841 | 17842 | 17843 | 17844 | 17845 | 17846 | 17847 | 17848 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| 35° CA-C, CA-T | 435 CA-C CA-T |

CAD Files & Drawings

| TORCH MODELS | CAD FILE | PDF DRAWING |

|---|---|---|

| Model 35° CA-C/CA-T w/Nozzle Body 13197 | 35° | 35° |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| Air-Cooled Curved MIG Guns One-Sheet |

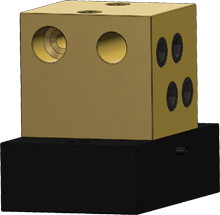

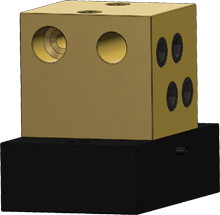

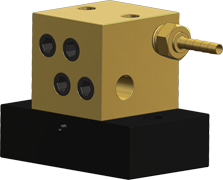

Utility Station #45184

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

More Info

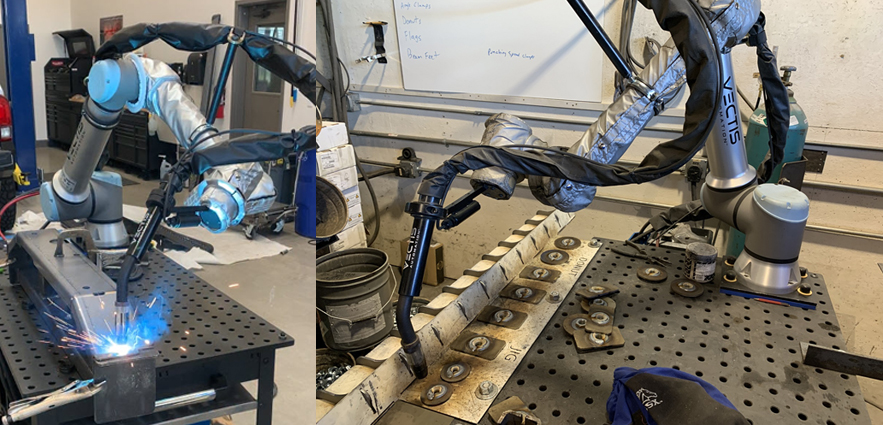

Cobot welding is a low risk, low-cost, easy-to-use answer for increasing welding productivity amid the ongoing shortage of skilled labor. The American Welding Society states that the average welder in the US is 55 years old and there is a projected shortage of 400,000 welders by 2024. To combat this shortage the Cobot or Collaborative Robot has been developed and implemented in many businesses. Cobots help boost productivity by reducing the learning curve, deployment time, risk, and cost of robotic welding.

D/F Machine Specialties, Inc has teamed up with Vectis Automation, LLC (Fort Collins, CO) . Vectis features the Heavy-Duty CA-C/CA-T Series 400 35 degree Air-Cooled MIG gun on the Cobot Welding Tool. The Vectis welding tool is powered by the industry-leading Universal Robots USA Inc (Ann Arbor, MI) UR10e arm. The Cobot arm has internal safety sensors that allow it to work in close proximity to humans, eliminating the need for permanent barriers. Cobots do not require a dedicated footprint and are portable; but are limited in reach and external axes - requiring smaller parts, manual re-positioning of parts, and/or repositioning of the Cobot welder system. This solution is geared primarily towards lower-volume smaller manufacturers who need quick deployment, flexibility, and ease-of-use. The Vectis Cobot Welder is around 25 to 40 percent less expensive than the all-in cost of a small traditional robot welder.

The Vectis Cobot system comes with all hardware provided fully integrated onto a 3 ft x 6 ft mobile modular fixturing cart, enabling fabricators to bring the Cobot to the work or the work to the Cobot with no anchoring nor dedicated footprint required. The Vectis Cobot Welding Tool does not need three-phase power but runs off a 120V wall outlet. The welder can run on anything between 208V and 575V, including 240V single-phase. The Cobot welder includes:

- A UR10e six-axis collaborative robot with 51 inch reach

- D/F Machine Specialties Heavy Duty air-cooled welding torch

- Intuitive programming on a 12 in touchscreen pendant with Let’s Weld Together programming interface

- A Rhino Cart® by Strong Hand Tools that includes 66 pieces of modular fixturing and a 30 in x 48 in mobile worktable

- A Miller 20 Series digital wire feeder and a Miller Invision 352 MPa MIG welder that includes Pulsed MIG waveforms and weld parameters controlled by the Cobot

- Peace-of-mind with a 30-day return policy, a rent-to-own program, lifetime technical support and added flexibility.

Contact Vectis Automation, LLC to discuss your unique COBOT application.

Phone: 970-852-5200

Email:

Air-Cooled 45° Curved Gun

Drawings Accessories

Overview

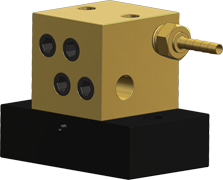

The rugged air-cooled CA-T/CA-C Series 400 45 degree curved gun configurations come pre-assembled and ready to install. All models have the feature of individual replaceable service connections with a removable cable hose sheath to add to the durability and long life of these gun assemblies.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- 400 Amp Current Capacity

- 1/0 Power Cable

- Accommodates Robotic Welding Systems

- Several Nozzle Body Configurations Available

- Heavy Duty Brass Inner Body

- Chrome Plated Brass Front End

- Heavy Duty Copper Nozzle

- High Temperature Insulation

Model Explanation

- CA-C - Curved, Air-cooled, Collet Action (Slip-In Tip)

- CA-T - Curved, Air-cooled, Threaded Current Tip

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|

| CA-C, CA-T | 400 amps CO2, 260 amps Argon |

1.8 lbs | .030"-1/16" Hard/Cored, 3/64"-1/16" AL |

445 CA-C CA-T |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BARREL HOUSING | DIAMETER OF NOZZLE BODY | NOZZLE TO BODY TUBE CLEARANCE |

|---|---|---|---|---|

| 45° CA-C, CA-T | 13.625" | 1.450" | 1.0625" | 5.375" |

Ordering Information

For Hard and Cored Wire

| DESCRIPTION | CODE NO. | ||||||||

| 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | 10 Ft. | 12 Ft. | 15 Ft. | |

| Model CA-C/CA-T w/ Nozzle Body 13197 |

17839-3 | 17839-4 | 17839-5 | 17839-6 | 17839-7 | 17839-8 | 17839-10 | 17839-12 | 17839-15 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| 45° CA-C, CA-T | 445 CA-C CA-T |

CAD Files & Drawings

| TORCH MODELS | CAD FILE | PDF DRAWING |

|---|---|---|

| Model 45° CA-C/CA-T w/Nozzle Body 13197 | 45° | 45° |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| Air-Cooled Curved MIG Guns One-Sheet |

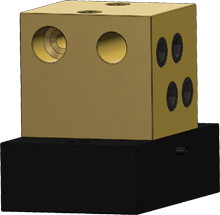

Utility Station #45184

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Air-Cooled 55° Curved Gun

Drawings Accessories

Overview

The rugged air-cooled CA-T/CA-C Series 400 55 degree curved gun configurations come pre-assembled and ready to install. All models have the feature of individual replaceable service connections with a removable cable hose sheath to add to the durability and long life of these gun assemblies.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- 400 Amp Current Capacity

- 1/0 Power Cable

- Accommodates Robotic Welding Systems

- Several Nozzle Body Configurations Available

- Heavy Duty Brass Inner Body

- Chrome Plated Brass Front End

- Heavy Duty Copper Nozzle

- High Temperature Insulation

Model Explanation

- CA-C - Curved, Air-cooled, Collet Action (Slip-In Tip)

- CA-T - Curved, Air-cooled, Threaded Current Tip

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|

| CA-C, CA-T | 400 amps CO2, 260 amps Argon |

1.8 lbs | .030"-1/16" Hard/Cored, 3/64"-1/16" AL |

455 CA-C CA-T |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BARREL HOUSING | DIAMETER OF NOZZLE BODY | NOZZLE TO BODY TUBE CLEARANCE |

|---|---|---|---|---|

| 55° CA-C, CA-T | 12.875" | 1.450" | 1.0625" | 5.375" |

Ordering Information

For Hard and Cored Wire

| DESCRIPTION | CODE NO. | ||||||||

| 3 Ft. | 4 Ft. | 5 Ft. | 6 Ft. | 7 Ft. | 8 Ft. | 10 Ft. | 12 Ft. | 15 Ft. | |

| Model CA-C/ CA-T w/ Nozzle Body 13197 |

15518 | 15524 | 15530 | 15536 | 15547 | 15558 | 15576 | 15577 | 15578 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| 55° CA-C, CA-T | 455 CA-C CA-T |

CAD Files & Drawings

| TORCH MODELS | CAD FILE | PDF DRAWING |

|---|---|---|

| Model 55° CA-C/CA-T w/Nozzle Body 13197 | 55° | 55° |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| Air-Cooled Curved MIG Guns One-Sheet |

Utility Station #45184

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.