Series A High Capacity Barrels

(11/16"-1" Gas Cup ID)

Drawings Accessories More Info

Overview

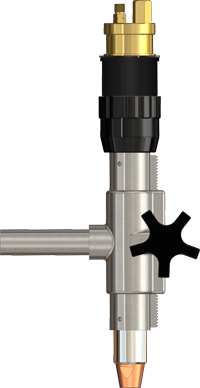

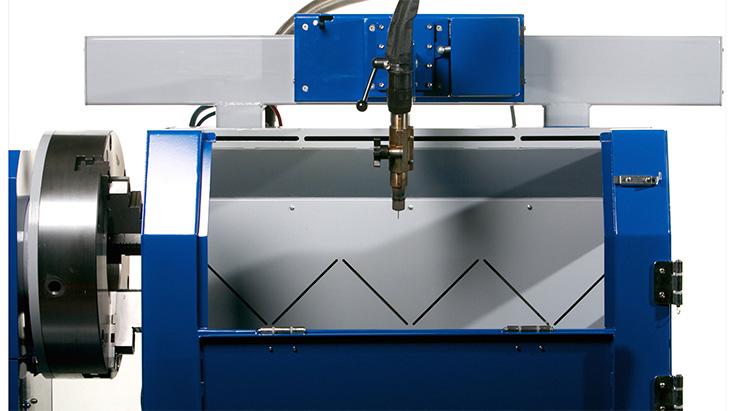

The fully Water-Cooled-to-the-Tip® Robotic MIG (GMAW) Torch Models NCM-W/C-T & HTM-W/C-T are applied to a Remote Mount Docking Spool® for high current single arc welding. These robotic torches are fully water cooled internally and externally. The internal body of the torch is water cooled, thus putting the water cooling on the tip. This has increased tip life up to 14 times longer. Also, because the water cooling is on the tip, this enables customers to use our less expensive 122 slip-in copper tips for many applications. The exterior water cooled nozzle is internally water cooled as well. There are no bulky external water lines in the way leading down getting caught or getting damaged by heat. Because of the superior internal and external water cooling of this torch, you can run the full range of wires from .030"-1/8", whether your job is aluminum, steel, stainless steel, hard, cored, flux cored, stellite or inconel wire, whether your job has 1000 degree preheat, high deposition or continuous duty cycles, this is the torch. Very similar in design to the Linde ST12, Guild ST12, and Abicor Binzel AUT 750 but with improvements and new features, and proven to be a superior replacement alternative for the Linde HW13, or now called the ESAB HW13, the D/F Machine Water-Cooled-to-the-Tip® Robotic Torches are designed to provide long trouble-free service. These Automatic Water-Cooled-to-the-Tip® Torches are available in 5" and 8" lengths. Each length is available with our standard size nozzles (1.125"), and our high capacity (series A) nozzles (1.445") for more gas coverage. You can switch between the standard nozzles and high capacity nozzles if you have the correct inner parts for each. With the various models available a contact assembly selection may be made to suit individual robot torch requirements.

The remote mount fully Water-Cooled-to-the-Tip® Docking Spool® accommodates two (2) water cooled nozzle assemblies. This arrangement is readily adaptable to dedicated or automatic Welding applications such as the Lincoln NA-3, NA-4, NA-5, and NA-5R. The equipment consists of four (4) basic components: a Utility Station, an intermediate Utilities Combination assembly, a High Deposition Docking Spool®, and a Water-Cooled Nozzle. The Docking Spool® is the principal component in this welding equipment arrangement. It accepts the utilities at the top end of the Spool and provides a means of accepting the water cooled nozzle at the lower end with superior water cooling. Several features important to a welding system are provided. Incorporated within the water channels of the Docking Spool® are check valves which provide a means of retaining residual water in the lines when the nozzle assembly is removed from the Docking Spool®. In addition a POSIT® Ring is provided at the upper end of the Docking Spool® which allows positive location in a Mounting Bracket to maintain dimensional stability.

Features

- Water Cooled Internally - Tip Recessed in Water Cooling

- Water Cooled Externally - Gas Cup Recessed in Water Cooling

- Up to 650 Amps Continuous Duty Cycle

- Up to 850 Amps Continuous with Dual Power Cables

- Adaptable to Any Wire Feeder or Power Source

- Withstands Preheat Upwards of 900 Degrees

Model Explanation

- NCM-W/C-T Series-A - Normal Duty, Collet Action (Slip-In Tip), Machine Barrel - Water-Cooled-to-the-Tip, High Capacity (Series A)

- HTM-W/C-T Series-A - Heavy Duty, Threaded Tip, Machine Barrel - Water-Cooled-to-the-Tip, High Capacity (Series A)

Model Specifications - A5" Torches

| MODEL | CURRENT CAPACITY |

WEIGHT w/ 5" NOZ. (APPROX.) |

COOLING REQUIRED |

RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| NCM-W/C-T A5" | 450 amps | 2.8 lbs | 3 quarts/min | .030"-5/32" Hard/Cored, 3/64"-1/8" AL |

534 (All A5" Noz.) |

| HTM-W/C-T A5" | 850 amps | 2.8 lbs | 3 quarts/min | .030"-5/32" Hard/Cored, 3/64"-1/8" AL |

Model Specifications - A8" Torches

| MODEL | CURRENT CAPACITY |

WEIGHT w/ 8" NOZ. (APPROX.) |

COOLING REQUIRED |

RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| NCM-W/C-T A8" | 450 amps | 3.5 lbs | 3 quarts/min | .030"-5/32" Hard/Cored, 3/64"-1/8" AL |

600 (All A8" Noz.) |

| HTM-W/C-T A8" | 850 amps | 3.5 lbs | 3 quarts/min | .030"-5/32" Hard/Cored, 3/64"-1/8" AL |

Barrel Dimensions

| MODEL | Length w/ 5" Nozzle | Length w/ 8" Nozzle | Diameter of Docking Spool Body | Diameter of W/C Nozzle |

|---|---|---|---|---|

| NCM-W/C-T A, HTM-W/C-T A | 9.25" | 12.25" | 1.875" | 1.445" |

Ordering Information (Complete Assemblies)

| DESCRIPTION | CODE NO. (NCM) | CODE NO. (HTM) |

|---|---|---|

| Series A5" Nozzle | 40747 | 40746 |

| Series A8" Nozzle | 40139 | 40156 |

| Add Footage Digit to Item Code Number for Length Required. Example: Require 40139 with 4 Ft. Water-In Hose Assembly: 40139-4 | ||

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| NCM-W/C-T A, HTM-W/C-T A (All A5" Nozzles) |

534 |

| NCM-W/C-T A, HTM-W/C-T A (All A8" Nozzles) |

600 |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| NCM-W/C-T A5" | 40747 | 40747 | 40747 |

| HTM-W/C-T A5" | 40746 | 40746 | 40746 |

| NCM-W/C-T A8" | 40139 | 40139 | 40139 |

| HTM-W/C-T A8" | 40156 | 40156 | 40156 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Choosing the Proper Chiller for Your Application |

|

| Torch Connection Options | |

| W/C Remote Mount Water-Cooled-to-the-Tip® One-Sheet |

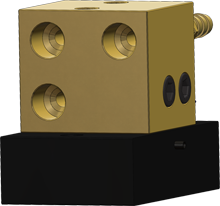

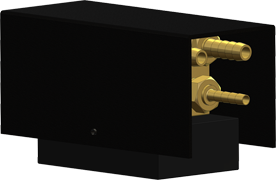

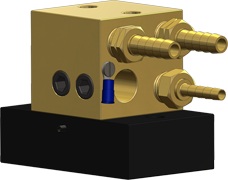

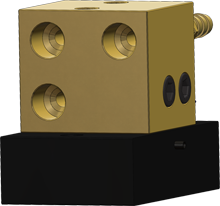

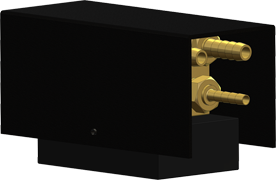

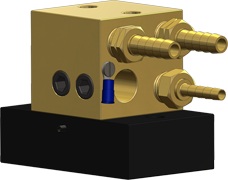

Utility Station #45196

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

More Info

The W/C Tip Torches can run the complete line of D/F standard size C122 DHP contact tips and the complete line of D/F standard size CrZr (chromium zirconium) long-life contact tips, as well as any custom current tip configuration you may need. .030" (.8mm), .035" (.9mm), .045" (1.2mm), .052" (1.4mm), 1/16" (1.6mm), 3/64" (1.2mm), 5/64" (2mm), 3/32" (2.4mm), 1/8" (3.2mm) and other diameters.

The W/C Tip Torches can run the complete line of D/F standard size C122 DHP contact tips and the complete line of D/F standard size CrZr (chromium zirconium) long-life contact tips, as well as any custom current tip configuration you may need. .030" (.8mm), .035" (.9mm), .045" (1.2mm), .052" (1.4mm), 1/16" (1.6mm), 3/64" (1.2mm), 5/64" (2mm), 3/32" (2.4mm), 1/8" (3.2mm) and other diameters.

W/C Tip D/F Machine Specialties torches are standard equipped with 1 water/out & power cable are rated at 650 amps (continuous duty cycles). These ratings are, however, dictated by the contact tip. The NCM (slip-in) series of contact tips is rated up to 450 amps (continuous duty cycles). If your welding application requires amperages above 450, you must change to the Heavy duty threaded CrZr (chromium zirconium) series of contact tips.

These automatic machine welding assemblies are designated by torch models. The model NCM (slip-in contact tip) has a current capacity 450 amps in argon shielding. Like the ESAB ST-12, these accommodate slip-in current tips fastened by a collet action nut. The wire diameter range with hard wire is .030"-1/16", cored wire .035"-1/8", and aluminum wire range of .035"-3/32".

The torch model HTM (threaded contact tip) has a current capacity range of 650 amperes. Rating will be contingent on the combination of current tip and shielding gas to be used. The model HTM employs threaded CrZr (chromium zirconium copper) current tips and will accommodate .030" - 1/16" hard wire, .035" - 1/8" cored wire and 3/64" - 3/32" aluminum wires.

In some instances C122 DHP is adequate, but for stainless steel and stiff, high column strength or abrasive wires such as flux cored / metal cored, CrZr is the correct choice. D/F Machine Specialties can increase several key characteristics creating a higher-quality consumable with increased conductivity, even higher softening temperature and improved hardness. This means a reduction in "arc start failures" and increased tip life. Copper chromium zirconium (CuCrZr) contact tips increase productivity.

W/C Tip model torches can also be retrofit to have 2 water/out & power cables increasing the continuous duty cycle rating to 850 amps. These amperages require the use of the HTM or threaded series of chromium zirconium (CrZr) current tips.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. Water outlet temperature should not exceed 27°C (80°F). The torch’s water out & power cable is not cooled until the coolant has gone through the torch and out the water out & power cable. If water is not flowing through the D/F torch for at least 1 minute prior to striking an arc, when you apply the power and water hits the “hot” water/out & power cable, you will generate steam. Steam can damage the torches internals in seconds causing a leak. It can also blow out the torches water/out & power cable. A flow switch can be installed after the return line ensuring that coolant is present at the return line prior to striking an arc. When High-Deposition GMAW, high current density, high amperages, preheat, or extended periods of arc time are used, a refrigerated liquid chiller with a larger reservoir is required. Precise temperature control maintains the cooling at a constant 13°C (55°F) temperature, thus prolonging the life of the welding equipment and more specifically extending the service life of the gas nozzle and current tip. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Standard Barrels

(7/16"-3/4" Gas Cup ID)

Drawings Accessories More Info

Overview

The fully Water-Cooled-to-the-Tip® Models NCM-W/C-T & HTM-W/C-T Remote Mount Robotic Machine Torches offer the same features as those described for the machine barrels above. These torches feature the 1.125" smaller O.D. water-cooled nozzle for hard-to-reach, limited access areas. Very similar in design to the Union Carbide Linde/ESAB ST-12, Guild ST-12 and Abicor Binzel AUT 750, but with improvements and new features, and proven to be a superior replacement alternative for the Linde HW-13, or now called the ESAB HW-13, the D/F Machine robotic guns (Water-Cooled-to-the-Tip® Torches) are designed to provide long trouble-free service.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

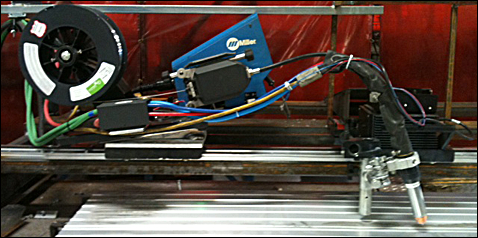

Red-D-Arc RDA Port-A-Weld System (PWS)

Contact Red-D-Arc Weld Automation to discuss your unique application.

Phone: 866-733-3272

Weld Automation Technical Sales: 225-290-2128

Features

- Water Cooled Internally - Tip Recessed in Water Cooling

- Water Cooled Externally - Gas Cup Recessed in Water Cooling

- Up to 650 Amps Continuous Duty Cycle

- Up to 850 Amps Continuous with Dual Power Cables

- Adaptable to Any Wire Feeder or Power Source

- Withstands Preheat Upwards of 900 Degrees

Model Explanation

- NCM-W/C-T - Normal Duty, Collet Action (Slip-In Tip), Machine Barrel - Water-Cooled-to-the-Tip

- HTM-W/C-T - Heavy Duty, Threaded Tip, Machine Barrel - Water-Cooled-to-the-Tip

Model Specifications - Standard 5" Torches

| MODEL | CURRENT CAPACITY |

WEIGHT w/ 5" NOZ. (APPROX.) |

COOLING REQUIRED |

RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| NCM-W/C-T 5" | 450 amps | 2.8 lbs | 3 quarts/min | .030"-5/32" Hard/Cored, 3/64"-1/8" AL |

534 (All 5" Noz.) |

| HTM-W/C-T 5" | 850 amps | 2.8 lbs | 3 quarts/min | .030"-5/32" Hard/Cored, 3/64"-1/8" AL |

Model Specifications - Standard 8" Torches

| MODEL | CURRENT CAPACITY |

WEIGHT w/ 8" NOZ. (APPROX.) |

COOLING REQUIRED |

RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| NCM-W/C-T 8" | 450 amps | 3.5 lbs | 3 quarts/min | .030"-5/32" Hard/Cored, 3/64"-1/8" AL |

600 (All 8" Noz.) |

| HTM-W/C-T 8" | 850 amps | 3.5 lbs | 3 quarts/min | .030"-5/32" Hard/Cored, 3/64"-1/8" AL |

Barrel Dimensions

| MODEL | Length w/ 5" Nozzle | Length w/ 8" Nozzle | Diameter of Docking Spool Body | Diameter of W/C Nozzle |

|---|---|---|---|---|

| NCM-W/C-T, HTM-W/C-T | 9.25" | 12.25" | 1.875" | 1.125" |

Ordering Information (Complete Assemblies)

| DESCRIPTION | CODE NO. (NCM) | CODE NO. (HTM) |

|---|---|---|

| Standard 5" Nozzle | 40748 | 40749 |

| Standard 8" Nozzle | 40138 | 40155 |

| Add Footage Digit to Item Code Number for Length Required. Example: Require 40138 with 4 Ft. Water-In Hose Assembly: 40138-4 | ||

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| NCM-W/C-T, HTM-W/C-T (All 5" Nozzles) |

534 |

| NCM-W/C-T, HTM-W/C-T (All 8" Nozzles) |

600 |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| NCM-W/C-T 5" | 40748 | 40748 | 40748 |

| HTM-W/C-T 5" | 40749 | 40749 | 40749 |

| NCM-W/C-T 8" | 40138 | 40138 | 40138 |

| HTM-W/C-T 8" | 40155 | 40155 | 40155 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Choosing the Proper Chiller for Your Application |

|

| Torch Connection Options | |

| W/C Remote Mount Water-Cooled-to-the-Tip® One-Sheet |

Utility Station #45196

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Torch Rack #30418 and Rack Mount

An optional D/F Torch Rack #30418 can be used on any torch with an 8" long, 1.125" diameter water-cooled nozzle. The rack slips right over the water-cooled nozzle and is secured with 4 set screws. The rack can then be dropped into a BUG-O BUG-5188 Rack Holder. The rack has a 32 pitch gear, and with the rack holder makes torch head positioning very easy. See the images below right. See the Torch and Rack Mount product page for more information

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

D/F #30421 Sub-Arc Attachment

The D/F Water-Cooled-to-the-Tip® Machine Barrels used with the D/F Submerged Arc Attachment are the industry's most advanced sub-arc torches for mobile, hard automation, and robotic feeding equipment, and will help achieve new levels of welding performance and operational efficency. Whether your application is bridge decking, pressure vessels, panel line, seamers, pipe mill integrator solutions, or submerged arc robotic welding, the D/F sub arc choices are designed to improve weld quality, reduce welding and operational costs, and increase weld team productivity.

More Info

The following is a press release given by Hardbanding Solutions.

"Hardbanding Solutions (Europe) Ltd

Gauchalland Works

Ayr Road

Galston

Ayrshire,

Scotland. KA4 8LE

Tel (01563) 822862

Fax (01563) 820015

Company Registration No. SC404792

VAT No. 118317526

The First Dedicated Hardbanding Equipment Manufacturer in Europe has Arrived, and They Chose the DF Torch.

Hardbanding Solutions Europe is a young company based in rural South West Scotland. Incorporated almost 5 years ago, they established themselves as a ‘Technical Centre’ for US hardbanding wires such as Duraband NC, manufactured by Postle Industries in Cleveland, Ohio.

Last year the company decided to expand its operations, and the logical choice was to design and build specialized hardbanding equipment. With more than three decades of experience in hardbanding between the three directors of the company, they knew that the welding equipment had to be built to withstand some rough treatment. Hardbanding involves the protection of drill pipe tool joints and casing from wear using a hardfacing process, for oil and gas drilling operations. These machines must be capable of running all day and night, in both factory and field conditions.

The units are made entirely of parts from the USA and the EU. The choice of welding torch was vital to reliability, as it’s often the torch that will come under the most strain. Darren Mathieson, the companies technical director, commented, “We needed a torch which was robust, and extremely reliable. A torch that would continue to work at full capacity after taking a few, inevitable knocks. The arc energy and heat involved in hardbanding is high and our well-organized customers have the welding unit working almost constantly. So we chose the DF machine style barrel, water-cooled to the tip. We have not been disappointed, they perform very well for this application.”

You can see the full range of hardbanding equipment, and find out a little more about the company, at their new website.. www.hardbandingequipment.com"