Air-Cooled MIG Guns - Direct Mount

Drawings Accessories

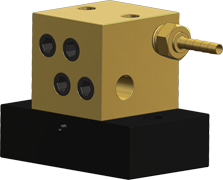

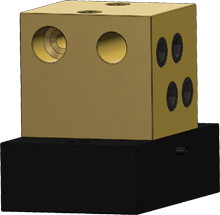

Overview

This air-cooled machine torch positive contact assembly is readily adaptable to automatic welding for multi-process wire welding in the automotive manufacturing, pressure vessels/heavy plate, or job shop fabrication industries, particularly when code quality work is required. It is furnished completely assembled and ready for installation. Both versions of the single arc contact nozzle assembly (models MAC & MAT) have the feature of individual replaceable service connections to add to the durability and long life of the barrel assemblies for boom mounting – your top choice for neat, uncluttered semiautomatic work stations. This arrangement is readily adaptable to Dedicated or Automatic Welding applications such as the Lincoln NA-3, NA-4, NA-5 & NA-5R Automatic wire feeders, and Power Feed 10M wire feeders. Direct mounting is accomplished by the D/F Machine Specialties Lincoln Electric NA3, NA4, NA5, NA5R Feeder Adapter (DF part #16880), Power Feed 10M wire feeder adapter (DF part #13480 - Lincoln Power Feed 10, LF72, LF74), and Miller series, ESAB, Euro Connector and Tweco #4 power pins, utilizing interconnections to the welding head or wire drive. Shielding gas is accommodated by a horizontal gas hose connection.

The D/F air-cooled automatic machine torch #12705 is a superior replacement alternative for the Lincoln Electric NA-5 & NA-5R feeders with K148A & K148B torches. The D/F Machine automatic air-cooled positive contact assemblies are designed to provide long trouble-free service. With the various models available, a contact assembly selection may be made to suit individual torch requirements.

The direct mount air-cooled contact assembly can accommodate three (3) different air-cooled nozzle assemblies. This arrangement is readily adaptable to dedicated or automatic welding applications such as the Lincoln NA-3, NA-4 & NA-5 automatic wire feeders.

The A/C Torches can run the complete line of D/F standard size C122 DHP contact tips and the complete line of D/F standard size CrZr (chromium zirconium) long-life contact tips, as well as any custom current tip configuration you may need. .030" (.8mm), .035" (.9mm), .045" (1.2mm), .052" (1.4mm), 1/16" (1.6mm), 3/64" (1.2mm), 5/64" (2mm), 3/32" (2.4mm), 1/8" (3.2mm) and other diameters.

These automatic machine welding assemblies are designated by torch models. The model NCM (slip-in Contact Tip) has a current capacity range of 400 amps in CO2 and 260 amps in argon shielding. These accommodate slip-in current tips fastened by a collet action nut. The wire diameter range with hard wire is .030"-1/16", cored wire .035"-1/8", and aluminum wire range of .035"-3/32".

The torch model HTM (threaded contact tip) has a current capacity range of 400 amps in CO2 and 260 amps in argon shielding. Rating will be contingent on the combination of current tip and shielding gas to be used. The model HTM employs threaded CrZr (chromium zirconium copper) current tips and will accommodate .030" - 1/16" hard wire, .035" – 1/8" cored wire and 3/64" - 3/32" aluminum wires.

In some instances C122 DHP is adequate, but for stainless steel and stiff, high column strength or abrasive wires such as flux cored / metal cored, CrZr is the correct choice. D/F Machine Specialties can increase several key characteristics creating a higher-quality consumable with increased conductivity, even higher softening temperature and improved hardness. This means a reduction in "arc start failures" and increased tip life. Copper chromium zirconium (CuCrZr) contact tips increase productivity.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- 400 Amp CO2, 260 Amp Argon Current Capacity

- Power Cable Lug - Accepts 1/0 and 2/0 Power Cables

- Accommodates Robotic Welding Systems

- Several Nozzle Body Configurations Available

- Heavy Duty Brass Inner Body

- Chrome Plated Brass Front End

- Heavy Duty Copper Nozzle

- High Temperature Insulation

Model Explanation

- MAC - Machine, Air-cooled, Collet Action (Slip-In Tip)

- MAT - Machine, Air-cooled, Threaded Current Tip

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|

| MAC, MAT | 400 amps CO2, 260 amps Argon |

1.12 lbs | .030"-1/16" Hard/Cored | 654AM |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY |

|---|---|---|

| MAC, MAT | 8.625" | 1.250" |

Ordering Information

| DESCRIPTION | CODE NO. |

|---|---|

| MAC - Slip-In Tip | |

| MAC-05 - Nozzle Body 13176 | 12705 |

| MAT - Threaded Tip | |

| MAT-07 - Nozzle Body 13176 | 12707 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| MAC, MAT | 654AM |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| MAC-05 | 12705 | 12705 | 12705 |

| MAT-07 | 12707 | 12707 | 12707 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| Air-Cooled MIG Torches One-Sheet |

Utility Station #45184

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Air-Cooled MIG Guns - Direct Mount

Short Barrel

Drawings Accessories

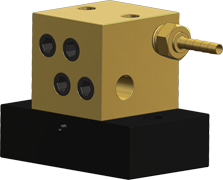

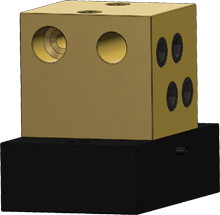

Overview

This air-cooled short machine torch single arc positive contact nozzle assembly is readily adaptable to automatic welding. It is furnished completely assembled and ready for installation. Both the MAC and MAT models have the feature of individual replaceable service connections to add to the durability and long life of the barrel assemblies for single arc welding at high currents. This arrangement is readily adaptable to dedicated or automatic welding applications with the Power Feed 10A Controller (K2362-1) built on the enduring and trusted foundation of the NA-5 controller to be used with the Lincoln NA-3, NA-4, NA-5R, LN-10 & DH-10 automatic wire feeders, boom wire feeders; 10M single or dual industrial wire feeders (K2314-1 Power Feed 10M Single Boom Model, Power Feed 10M Dual Boom Model K2316-1), and bench wire feeders; 10M single or dual industrial wire feeders (K2230-1 Power Feed 10M Single Bench Model, K2234-1 Power Feed 10M Dual Bench Model). Direct mounting is accomplished by utilizing interconnections to the welding head or wire drive. Shielding gas is accommodated by a horizontal connection. The contact nozzle assembly has numerous variations for different nozzle configurations with different sized gas cups and contact tips for getting into difficult or hard to reach areas.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- 400 Amp CO2, 260 Amp Argon Current Capacity

- Power Cable Lug - Accepts 1/0 and 2/0 Power Cables

- Accommodates Robotic Welding Systems

- Several Nozzle Body Configurations Available

- Heavy Duty Brass Inner Body

- Chrome Plated Brass Front End

- Heavy Duty Copper Nozzle

- High Temperature Insulation

Model Explanation

- MAC - Machine, Air-cooled, Collet Action (Slip-In Tip)

- MAT - Machine, Air-cooled, Threaded Current Tip

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|

| MAC, MAT | 400 amps CO2, 260 amps Argon |

1.10 lbs | .030"-1/16" Hard/Cored | 652AM |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY |

|---|---|---|

| MAC, MAT | 6.625" | 1.250" |

Ordering Information

| DESCRIPTION | CODE NO. |

|---|---|

| MAC - Slip-In Tip | |

| MAC-98 - Nozzle Body 13176 | 12698 |

| MAT - Threaded Tip | |

| MAT-96 - Nozzle Body 13176 | 12696 |

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| MAC, MAT | 652AM |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| MAC-98 | 12698 | 12698 | 12698 |

| MAT-96 | 12696 | 12696 | 12696 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| Air-Cooled MIG Torches One-Sheet |

Utility Station #45184

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. For D/F Air-Cooled Torches, the gas hose and power cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front of the Utility Station. Into the back of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.