W/C Curved 22° & 45° Machine Barrels

Drawings Accessories More Info

Overview

The versatile Water-Cooled Machine Torch models NCC/LRN, HTC/LRN, NCC/N, & HTC/N can be used for a wide range of applications. The machine barrels may be applied to either a remote or direct mount Docking Spools®. With the various angles (5°, 22°, 35°, 45°, and 60°) and lengths available (Long Reach 12.5" and Short 5"), a selection may be made to suit individual requirements.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. If you are currently having problems using the Tregaskiss Tough Gun I.C.E™ (Integrated Cooling Enhancer) because of high amperages, long duty cycles resulting in torches overheating, expensive gas diffusers, and short consumable life, this series of D/F Robotic Water-Cooled Torches is a superior alternative. There are no exterior water lines that can be damaged running down the outside of the torch. The D/F LRN torches are completely water-cooled throughout. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

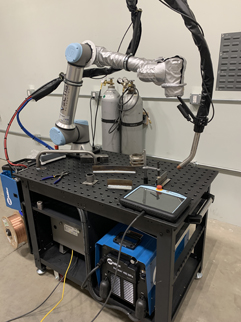

Contact Vectis Automation, LLC to discuss your unique COBOT application.

Phone: 970-852-5200

Email:

Features

- Water Cooled Internally - Tip Recessed in Water Cooling

- Water Cooled Externally - Gas Cup Recessed in Water Cooling

- Up to 650 Amps Continuous Duty Cycle

- Up to 850 Amps Continuous with Dual Power Cables

- Adaptable to Any Wire Feeder or Power Source

- Withstands Preheat Upwards of 900 Degrees

Model Explanation

- NCC-N - Normal Duty, Collet Action (Slip-In Tip), Curved - Short 5" Nozzle

- HTC-N - Heavy Duty, Threaded Tip, Curved - Short 5" Nozzle

- NCC-LRN - Normal Duty, Collet Action (Slip-In Tip), Curved - Long Rreach Nozzle

- HTC-LRN - Heavy Duty, Threaded Tip, Curved - Long Rreach Nozzle

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED |

RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| NCC-LRN 5° Standard Long Reach |

400 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

536-5 |

| HTC-LRN 5° Standard Long Reach |

500 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-N 22° Short 5" |

400 amps | 3.6 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

536NB (All 22°) |

| HTC-N 22° Short 5" |

500 amps | 3.6 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN 22° Standard Long Reach |

400 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| HTC-LRN 22° Standard Long Reach |

500 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN 30° Standard Long Reach |

400 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

542-30 |

| HTC-LRN 30° Standard Long Reach |

500 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN 35° Standard Long Reach |

400 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

542-35 |

| HTC-LRN 35° Standard Long Reach |

500 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN 45° Standard Long Reach |

400 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

536NB |

| HTC-LRN 45° Standard Long Reach |

500 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN 45° Standard Long Reach 4" Radius |

400 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

537NB4R-45 |

| HTC-LRN 45° Standard Long Reach 4" Radius |

500 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN 60° Standard Long Reach |

400 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

542-60 Standard |

| HTC-LRN 60° Standard Long Reach |

500 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN 90° Standard Long Reach |

400 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

542-90 Standard |

| HTC-LRN 90° Standard Long Reach |

500 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY | DIAMETER OF W/C NOZZLE |

|---|---|---|---|

| NCC-LRN 5°, HTC-LRN 5° | 12.641" | 1.875" | 1.125" |

| 5" NCC-N 22°, 5" HTC-N 22° | 8.516" | 1.875" | 1.125" |

| NCC-LRN 22°, HTC-LRN 22° | 12.641" | 1.875" | 1.125" |

| NCC-LRN 30°, HTC-LRN 30° | 12.500" | 1.875" | 1.125" |

| NCC-LRN 35°, HTC-LRN 35° | 12.500" | 1.875" | 1.125" |

| NCC-LRN 45°, HTC-LRN 45° | 12.500" | 1.875" | 1.125" |

| NCC-LRN 60°, HTC-LRN 60° | 11.250" | 1.875" | 1.125" |

| NCC-LRN 90°, HTC-LRN 90° | 9.797" | 1.875" | 1.125" |

Ordering Information (Complete Assemblies)

| DESCRIPTION | CODE NO. | |

| COMPLETE ASSEMBLIES |

COMPLETE NOZZLE ONLY |

|

| NCC-N & HTC-N Curved 5° Short 5" | 48214 | 48212 |

| NCC-N & HTC-N Curved 22° Short 5" | 40775 | 48227 |

| NCC-LRN & HTC-LRN Curved 5° Long Reach | 48209 | 48207 |

| NCC-LRN & HTC-LRN Curved 22° Long Reach | 40785NB | 48225NB |

| NCM-LRN & HTM-LRN Curved 30° Long Reach | 40711NB | 48250NB |

| NCM-LRN & HTM-LRN Curved 35° Long Reach | 40712NB | 48242NB |

| NCC-LRN & HTC-LRN Curved 45° Long Reach | 40788NB | 48221NB |

| NCC-LRN & HTC-LRN Curved 45° Long Reach (4" Radius for 1/16" or larger wire) | 40789NB4R-45 | 48254NB4R-45 |

| NCC-LRN & HTC-LRN Curved 60° Long Reach | 48230NB | 48121NB-60 |

| NCC-LRN & HTC-LRN Curved 90° Long Reach | 40725 | 48121-90 |

| Add Footage Digit to Item Code Number for Length Required. Example: Require 40785 with 4 Ft. Utilities: 40785NB-4 |

||

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| NCC-LRN, HTC-LRN 5° | 536-5 |

| NCC-LRN, HTC-LRN, NCC-N, HTC-N (All 22°) |

536NB |

| NCC-LRN 30°, HTC-LRN 30° | 542-30 |

| NCC-LRN 35°, HTC-LRN 35° | 542-35 |

| NCC-LRN 45°, HTC-LRN 45° | 536NB |

| NCC-LRN 45°, HTC-LRN 45° 4" Radius | 537NB4R-45 |

| NCC-LRN 60°, HTC-LRN 60° | 542-60 |

| NCC-LRN 90°, HTC-LRN 90° | 542-90 |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| NCC-LRN 5°, HTC-LRN 5° | 48209 | 48209 | 48209 |

| NCC-N 22°, HTC-N 22° (Short 5" Barrel) | 40775 | 40775 | 40775 |

| NCC-LRN 22°, HTC-LRN 22° | 40785 | 40785 | 40785 |

| NCC-LRN 30°, HTC-LRN 30° | 40711 | 40711 | 40711 |

| NCC-LRN 35°, HTC-LRN 35° | 40712 | 40712 | 40712 |

| NCC-LRN 45°, HTC-LRN 45° | 40788 | 40788 | 40788 |

| NCC-LRN 60°, HTC-LRN 60° | 48230 | 48230 | 48230 |

| NCC-LRN 90°, HTC-LRN 90° | 40725 | 40725 | 40725 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| W/C 22° & 45° Curved Barrels One-Sheet |

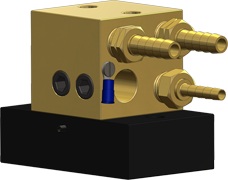

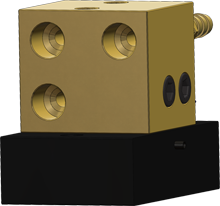

Utility Station #45196

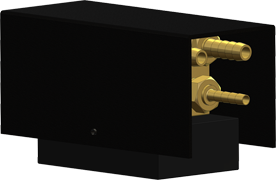

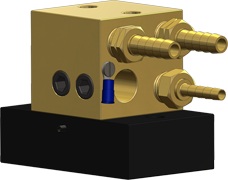

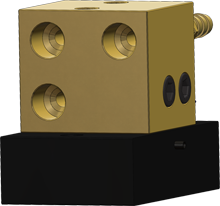

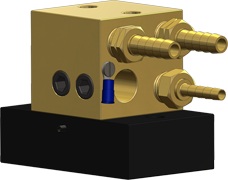

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Robotic Welding Systems

Robotic welding is suitable for any welding process designed for automation in that it requires repetitive tasks on similar pieces. Robotic welding also works well when there are welds on more than one axis, or where access to the pieces is difficult. When programmed, robots perform the same welds every time on work-pieces of the same dimensions and specifications. In about 80 percent of applications, robotic welding is used with the solid wire GMAW process.

Throughout the years, D/F Machine Specialties’ MIG & TIG torches were used exclusively on the following FANUC Robotics System 100 Models - ArcMate 100, ArcMate 100i, ArcMate 100iB, and ArcMate 100iB/6S. The typical power source used with the D/F Torches on the Fanuc robotic cell was a Lincoln Powerwave 450 power supply.

QUALITY: Higher quality welds are maintained with the mechanical consistency of the robot. Consistency is provided by the precise movement of the robot arm and torch, as well as the wire feed speed and travel speed. Robotic welding creates a more consistent weld strength and better weld appearance.

PRODUCTION COSTS: Robotic Welding reduces productions costs by using fewer welding consumables and producing fewer scrapped parts.

RETURN ON INVESTMENT: The ROI for an industrial welding robot usually appears after about 6 months. Increased productivity, decreased labor, and many other benefits of automated welding factor into faster ROI times.

PRODUCTIVITY: The repeatability and speed of the robotic welding system provides increased productivity. Robotic welding can produce at a higher rate than human welding, and allow for a more productive workforce.

SAFETY: Employers find that they have fewer employee accidents and lower Workers Comp claims when they change to robotic welding.

There are two popular types of industrial welding robots, articulating robots and rectilinear robots. Robotics control the movement in each of these robot types by rotating a wrist in space. These two types are defined as follows:

1. Rectilinear robots move in line in any of three axes (X, Y, Z). In addition to linear movement of the robot along axes there is a wrist attached to the robot to allow rotational movement. This creates a robotic working zone that is box shaped.

2. Articulating robots employ arms and rotating joints. These robots move like a human arm with a rotating wrist at the end. This creates an irregularly shaped robotic working zone. Most articulated welding robots feature six axes and function as part of a robotic system or workcell.

Robotic welding systems reduce production costs and improve quality with consistency and repeatability. Consistency is provided by the precise movement of the robot arm and torch, as well as the wire feed speed and travel speed. The repeatability of the welding robotic system provides increased productivity. To create a successful robotic welding system, you need an integrator who can properly design a program that integrates the parts to be welded and the robotic cell and tooling. Robotic welding is simpler than one might think, but it requires precise measurements and an understanding of parameters of the equipment. It is important to team with an integrator with the experience and customer service demanded by your robotic needs.

Benefits of Robotic Welding:

- Reduce Production Costs - Fewer scrapped parts, reduced amount of welding consumables needed

- Improved Product Quality - More consistent weld strength, better weld appearance and consistent quality

- Increased Productivity - Robotic welding produces at a higher rate than human welding

- Cost Justification - Lower costs of robotic equipment, scarcity of highly skilled labor

- Improved Safety - Fewer employee accidents / Lower Workers Comp claims, more productive workforce

Things to consider before beginning a new robotic welding project:

- The parts to be welded

- Weld joint accessibility

- Repeatability of the parts

- Fixture requirements

Fanuc Robots

The Fanuc ArcMate 100iB/6S welding cell comprises a six axes FANUC Robotics ArcMate 100iB robot within a self-contained enclosure. The ArcMate 100iB is a six-axis, modular construction, electric servo-driven robot designed for precise, high-speed welding and cutting. Based on its simple and reliable construction, the ArcMate 100iB provides accurate and consistent path performance. The R-J3iB Controller and easy-to-use ArcTool software provide reliable performance with high productivity. Components loaded into jigs on a manually operated table are loaded outside the cell while the robot welds components within the cell.

The system is designed and manufactured by FANUC Robotics as a self contained unit which is delivered ready assembled and only requires services to be connected before operation on site.

The new ARC Mate 100iB/6S, the latest generation arc welding robot, has a compact design with improved motion range and speed. The compact yet flexible design simplifies installation, maximizes reach capability within confined areas and enables high-density installation of robots and peripherals.

| Technical Data for Fanuc ArcMate 100iB | |

| Controlled Axes | 6 |

| Payload | 6 kg |

| Maximum Reach | 1373 mm |

| Repeatability | ±0.08 mm |

| Weight | 138 kg |

| Mounting Positions | Floor, Invert, Wall |

| Maximum Speed | |

| J1-axis | 150°/s |

| J2-axis | 160°/s |

| J3-axis | 170°/s |

| J4-axis | 400°/s |

| J5-axis | 400°/s |

| J6-axis | 520°/s |

Benefits

- Features highest motion speeds in class for maximum performance and productivity.

- Best in class reach versus stroke ratio.

- Compact design simplifies installation and transportation of system.

- Fastest wrist axes in class minimizes air cut time by quickly reorienting the weld torch.

- High axis speeds maximize product throughput.

- Design allows for extremely small weld cells or a high density of arc welding torches in a given area.

Features

- Slim wrist size enables the robot to enter into smaller openings in the work space.

- 951 mm reach.951 mm reach.

- 622 mm stroke.

- 6 kg payload on faceplate.

- All axes mechanical brakes.

- Absolute encoder positioning.

- TurboMoveTM advanced servo control features allow quick and smooth point-to-point motion, which increases arc on-time and throughput.

- “Plug and play” simplicity with Lincoln Electric's Power Wave or STTTM (Surface Tension Transfer) power sources.

- Compatible with all major brands of welding equipment.

- Arc welding teach pendant with application-specific hard keys offers intuitive control over the process.

- Interfaces with most types of servo-driven or indexing positioners.

- Multiple mounting positions include upright, inverted, wall or angle mount with no changes to the mechanical unit.

- Sealed bearings and drives provide protection and improve reliability.

- RV reducer drivetrain with integral bearings provides rigidity and performance in a compact package.

Options

- EMI shielding kits for TIG (GTAW), plasma (PAW) and plasma cutting (PAC) allow operation in harsh EMI (electro-magnetic interference) environments.

- Additional process welding I/O integrates multi-channel welding equipment such as 4 channel TIG and 3 channel MIG (STT).

- Various robot connection cable lengths for flexible cabinet placement and optional track rated cables.

- J1 axis stroke modification kit.

- Auxiliary axis packages for integration into welding.

Note: ARC Mate is a registered Trademark of FANUC LTD.

FANUC Ferris Wheel System - The FANUC Ferris Wheel Workcell is designed to save space and enhance operator safety.

FANUC Gantry System - A gantry robot system mounts a robot arm on an overhead track, creating a horizontal plane that the robot can travel and extending the work envelope.

FANUC Manual Turntable System - A FANUC workcell with a manual turntable is an ideal solution for applications that require loading and unloading parts while the robot is in operation.

FANUC Stationary Table System - FANUC robots offer excellent ROI in welding and handling applications. Realize incredible savings with a FANUC turnkey workcell that includes a single or dual stationary work table.

FANUC Track System - The Dual FANUC Track System allows for nearly 63 feet of travel along a servo controlled track to accommodate applications with large parts and multiple processes.

FANUC Turntable System - Order a workcell that fits your needs! Available in any size, this workcell pairs a 180 degree table with one or two FANUC robot arms for maximum productivity.

Shop Gains Productive Edge with Robotic Welding

F.R. Custom Metal Fabricating Ltd. made a sound investment in the future with the recent purchase of its first robotic welding cell. Faced with a contract to produce a large volume of pallet truck handles, the fabricating shop found it increasingly difficult to maintain the skilled workforce of welders needed to produce consistent, high quality parts at the necessary volume. By adding a two-station Lincoln Electric automated welding system with D/F Machine Specialties torches, the firm is now able to meet production and quality goals without trying to find employees willing to work overtime.

F.R., a custom fabricator founded 28 years ago by its President, Alfred Nonnewitz, traditionally has specialized in lower volume, higher quality fabrications, particularly those involving tubular components. For the last three or four years, the company has been producing pallet truck handles on a contract that calls for increasingly higher volumes, now generally between 700 and 1,000 parts per week, according to Bill Nonnewitz, the founder's son.

F.R., a custom fabricator founded 28 years ago by its President, Alfred Nonnewitz, traditionally has specialized in lower volume, higher quality fabrications, particularly those involving tubular components. For the last three or four years, the company has been producing pallet truck handles on a contract that calls for increasingly higher volumes, now generally between 700 and 1,000 parts per week, according to Bill Nonnewitz, the founder's son.

As with most manufacturing firms throughout North America, F.R. was finding it increasingly difficult to hire the skilled workers needed to maintain the quality and volume of its production. And with today's busy lifestyle, employees were less willing to work long overtime hours to keep up with the demand.

After meeting with representatives of The Lincoln Electric Company's Automated Systems Group (ASG), Alfred and Bill Nonnewitz concluded that the benefits of automating the handle-welding operation would be worth the investment.

The result is a complete two-station work cell that incorporates a six-axis Fanuc ARC Mate™100i robot equipped with a SYSTEM R-J3™ controller, a Lincoln Power Wave® 450 power source, and a D/F Machine Specialties 22 degree LRN water-cooled torch (D/F #40785-4).

Safety was built into the welding cell with the addition of safety zone rings (limit switches) that prevent the robot and welding torch from going to the station where the operator is working on the next setup until the area is cleared. In addition, each station has a safety mat that prevents the robot from coming to that station if the operator is standing on the mat. Further safety protection is provided by a breakaway nozzle that minimizes damage in case the torch hits any part of the workstation or the parts being welded.

All components are mild steel, with the handle and brackets being 16 gauge and the tube being 14 gauge. Welds are made with .035" diameter Lincoln SuperArc® L-56™ (AWS ER70S-6) electrode, which includes extra deoxidizers that provide cleaning action and improve weld quality. Since the handles are used to move pallet trucks that weigh up to 5000 lbs., weld integrity is critical to meeting the stresses they must withstand. All welds are fillets, but the welds that join the round handle to the square tube are especially critical. Bill Nonnewitz explains, "The welding power source is capable of making a full regulated controlled weld without spatter or burn-through. Because we only have 1/16" on a side, the welds can't extend out very much. They have to be good, and the penetration has to be consistent."

Jim Grant explains that the entire workstation is modular and can be moved with a forklift. "It's essentially a plug-and-play robot that was placed on the floor as a complete unit, pre-programmed for the parts they make. Everything is mounted on a platform that keeps the units in proper relationship to one another and allows the cell to be moved easily to another location if needed."

The Lincoln PowerWave® 450 is a sophisticated power source that gives the company significant advantages, with cost savings that are expected to more than offset a slightly higher initial investment. First is the unit's capability for Pulsed MIG welding, an advanced welding mode that combines the best qualities of all other metal transfer modes without their disadvantages. Its lower heat input prevents burn-through on thin metals. Spatter and fume are reduced as well, which improves the working environment and reduces costs. Since only one wire size is required, wire and gas costs are also lower, and the process delivers higher deposition rates than other processes, so productivity is greater. In addition, the power source can be updated easily with new software, an important advantage that protects the company's investment.

The Fanuc ARC Mate™100i robot is designed with integral utilities to improve reliability and setup time. The wire feed motor cable, gas line and air line are all inside the robot arm. Its high motion speeds help improve productivity, and advanced servo-control features allow faster and smoother point-to-point motion.

The FANUC Robotics System R-J3 controller is completely integrated with the robot itself, which allows flexible work cell layout and easy installation. It utilizes the most advanced software with features that include welding restart, scratch start, and on-the-fly weld adjustment. Mirror image utility allows the programmer to shift an existing program and also to invert it, which is extremely useful with F.R. Custom Metal's two-station mirror-image cell. The program also allows starting and stopping the programmed welding sequence from the Teach Pendant, which features commands in English for ease of use.

While no comparative figures were kept, the improvements in product quality and productivity have been significant since the company added the robotic cell, and the labor shortages it experienced earlier have been minimized. Bill Nonnewitz says that, since installing the robotic system a few months ago, the company has already seen significant savings, both in reduced overtime costs and in rework and scrap losses.

W/C Curved 60° Machine Barrels

Drawings Accessories

Overview

The versatile Water-Cooled Machine Torch models NCC-LRN, NCC-LRN-L, HTC-LRN, & HTC-LRN-L can be used for a wide range of applications. The machine barrels may be applied to either a remote or direct mount Docking Spools®. With the various angles (22°, 30°, 35°, 45°, and 60°) and lengths available (Long Reach 11.250" and Extra Long-Long Reach 18.125"), a selection may be made to suit individual requirements.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. If you are currently having problems using the Tregaskiss Tough Gun I.C.E™ (Integrated Cooling Enhancer) because of high amperages, long duty cycles resulting in torches overheating, expensive gas diffusers, and short consumable life, this series of D/F Robotic Water-Cooled Torches is a superior alternative. There are no exterior water lines that can be damaged running down the outside of the torch. The D/F LRN torches are completely water-cooled throughout. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- Quick-Change - Interchange Between Short, Long, Straight or Curved Goosenecks

- Fully Water-Cooled Internally - Gas Cup Recessed in Water Cooling

- Up to 500 Amps Continuous Duty Cycle

- Adaptable to Any Wire Feeder or Power Source

- Withstands Preheat Upwards of 900 Degrees

Model Explanation

- NCC-LRN-L - Normal Duty, Collet Action (Slip-In Tip), Curved - Long Rreach Nozzle - Long

- HTC-LRN-L - Heavy Duty, Threaded Tip, Curved - Long Rreach Nozzle - Long

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED |

RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| NCC-LRN-L 5° Extra Long Reach |

400 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

546-05 Long |

| HTC-LRN-L 5° Extra Long Reach |

500 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN-L 22° Extra Long Reach |

400 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

546-22 Long |

| HTC-LRN-L 22° Extra Long Reach |

500 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN-L 30° Extra Long Reach |

400 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

546-30 Long |

| HTC-LRN-L 30° Extra Long Reach |

500 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN-L 35° Extra Long Reach |

400 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

546-35 Long |

| HTC-LRN-L 35° Extra Long Reach |

500 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN-L 45° Extra Long Reach |

400 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

546-45 Long |

| HTC-LRN-L 45° Extra Long Reach |

500 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN-L 60° Extra Long Reach |

400 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

546-60 Long | 6

| HTC-LRN-L 60° Extra Long Reach |

500 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCC-LRN-L 90° Extra Long Reach |

400 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

546-90 Long |

| HTC-LRN-L 90° Extra Long Reach |

500 amps | 4.8 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY | DIAMETER OF W/C NOZZLE |

|---|---|---|---|

| NCC-LRN 5° Extra Long Reach, HTC-LRN 5° Extra Long Reach |

18.125" | 1.875" | 1.125" |

| NCC-LRN 22° Extra Long Reach, HTC-LRN 22° Extra Long Reach |

18.125" | 1.875" | 1.125" |

| NCC-LRN 30° Extra Long Reach, HTC-LRN 30° Extra Long Reach |

18.125" | 1.875" | 1.125" |

| NCC-LRN 35° Extra Long Reach, HTC-LRN 35° Extra Long Reach |

18.125" | 1.875" | 1.125" |

| NCC-LRN 45° Extra Long Reach, HTC-LRN 45° Extra Long Reach |

18.125" | 1.875" | 1.125" |

| NCC-LRN 60° Extra Long Reach, HTC-LRN 60° Extra Long Reach |

18.125" | 1.875" | 1.125" |

| NCC-LRN 90° Extra Long Reach, HTC-LRN 90° Extra Long Reach |

18.125" | 1.875" | 1.125" |

Ordering Information

| DESCRIPTION | CODE NO. | |

| COMPLETE ASSEMBLIES |

COMPLETE NOZZLE ONLY |

|

| NCC-LRN-L & HTC-LRN-L Curved 5° Extra Long Reach | 48244NBL-05 | 48245NBL-05 |

| NCC-LRN-L & HTC-LRN-L Curved 22° Extra Long Reach | 48244NBL-22 | 48245NBL-22 |

| NCC-LRN-L & HTC-LRN-L Curved 30° Extra Long Reach | 48244NBL-30 | 48245NBL-30 |

| NCC-LRN-L & HTC-LRN-L Curved 35° Extra Long Reach | 48244NBL-35 | 48245NBL-35 |

| NCC-LRN-L & HTC-LRN-L Curved 45° Extra Long Reach | 48244NBL-45 | 48245NBL-45 |

| NCC-LRN-L & HTC-LRN-L Curved 60° Extra Long Reach | 48244NBL-60 | 48245NBL-60 |

| NCC-LRN-L & HTC-LRN-L Curved 90° Extra Long Reach | 48244NBL-90 | 48245NBL-90 |

| Add Footage Digit to Item Code Number for Length Required. Example: Require 48230 with 4 Ft. Utilities: 48230-4 |

||

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| NCC-LRN 5° Extra Long Reach, HTC-LRN 5° Extra Long Reach |

546-05 Long |

| NCC-LRN 22° Extra Long Reach, HTC-LRN 22° Extra Long Reach |

546-22 Long |

| NCC-LRN 30° Extra Long Reach, HTC-LRN 30° Extra Long Reach |

546-30 Long |

| NCC-LRN 35° Extra Long Reach, HTC-LRN 35° Extra Long Reach |

546-35 Long |

| NCC-LRN 45° Extra Long Reach, HTC-LRN 45° Extra Long Reach |

546-45 Long |

| NCC-LRN 60° Extra Long Reach, HTC-LRN 60° Extra Long Reach |

546-60 Long |

| NCC-LRN 90° Extra Long Reach, HTC-LRN 90° Extra Long Reach |

546-90 Long |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| NCC-LRN 22° Extra Long Reach, HTC-LRN 22° Extra Long Reach |

48244-22 | 48244-22 | 48244-22 |

| NCC-LRN 30° Extra Long Reach, HTC-LRN 30° Extra Long Reach |

48244-30 | 48244-30 | 48244-30 |

| NCC-LRN 35° Extra Long Reach, HTC-LRN 35° Extra Long Reach |

48244-35 | 48244-35 | 48244-35 |

| NCC-LRN 45° Extra Long Reach, HTC-LRN 45° Extra Long Reach |

48244-45 | 48244-45 | 48244-45 |

| NCC-LRN 60° Extra Long Reach, HTC-LRN 60° Extra Long Reach |

48244-60 | 48244-60 | 48244-60 |

| NCC-LRN 90° Extra Long Reach, HTC-LRN 90° Extra Long Reach |

48244-90 | 48244-90 | 48244-90 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options |

Utility Station #45196

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.

Straight Short & LRN Machine Barrels

Drawings Accessories

Overview

The versatile D/F quick change Water-Cooled Robotic Torch models NCM/LRN, HTM/LRN, NCM/N, & HTM/N can be used for a wide range of robotic applications. With the various angles and lengths available, a selection may be made to suit individual robotic requirements.

The composite modular design of the rugged, yet versatile, quick-disconnect model LRN (Long Reach 10" composite water-cooled nozzle) and the model N (short 5" composite water-cooled nozzle) torches allow the user to quickly change the swanneck (gooseneck) or cable assembly while maintaining tool center point, assuring accurate repeatability and continuous precision welding. These D/F robotic torches have a compact, stainless steel, water-cooled nozzle designed specifically to withstand unusually large amounts of reflected heat build-up and prolonged duty cycles. Water circulates internally through the docking spool to the nozzle and the tip, keeping the torches running cooler, and thus the torch and consumables last longer. Mounting is easy with the D/F Universal Robotic Mounting Arm. In the event that a component has to be adjusted or replaced, the docking spool makes this torch entirely serviceable and easy to repair or replace in seconds.

These welding assemblies are designated by torch models. The models NCM/LRN & NCM/N (slip-in contact tip) have a current capacity 500 amps in argon shielding. These accommodate slip-in current tips fastened by a collet action nut. The wire diameter range with hard wire is .030"-1/16", cored wire .035"-1/8", and aluminum wire range of .035"-3/32".

The torch models HTM/LRN & HTM/N (threaded contact tip) have a current capacity range of up to 650 amperes. Rating will be contingent on the combination of current tip and shielding gas to be used. The model HTM employs threaded CrZr (chromium zirconium copper) current tips and will accommodate .030" - 1/16" hard wire, .035" - 1/8" cored wire and 3/64" - 3/32" aluminum wires.

Standard assemblies have torch necks (water-cooled nozzles) that are either straight or bent at 22°, 35°, 45°, 60° or 90°, available in different lengths, and with cable assemblies and replacement docking spool bodies. The LRN & N series torches also share common consumables with the complete D/F product line.

The D/F torch is famous for the fact, that if it is chilled properly, the welder can grab the chrome front water-cooled barrel (not the copper gas nozzle/cup) of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. If you are currently having problems using the Tregaskiss Tough Gun I.C.E™ (Integrated Cooling Enhancer) because of high amperages, long duty cycles resulting in torches overheating, expensive gas diffusers, and short consumable life, this series of D/F Robotic Water-Cooled Torches is a superior alternative. There are no exterior water lines that can be damaged running down the outside of the torch. The D/F LRN torches are completely water-cooled throughout. Make certain the cooling water supply is at least the minimum flow rate of 1 gallon per minute (for each inner body), at 40 psi (80 psi maximum) with a 6 gallon reservoir and a recommended 30,000 BTU/hr cooling capacity. Gun ratings are affected by shielding gas used, arc time, cooling time and inlet water temperature. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

Each D/F Machine Specialties welding gun is fully assembled and ready to install. In order to make the installation complete, the code number, wire size, wire feeder make/model (Lincoln wire feeders, Miller wire feeders, Tweco wire feeders, ESAB wire feeders, & EURO Quick Disconnect wire feeders), and inlet (as needed) must be specified when ordering. If special welding tools or accessories other than those listed previously are required, please consult with the factory. Get the right feeder adapter connection to fit your MIG wire feeder.

Features

- Quick-Change - Interchange Between Short, Long, Straight or Curved Goosenecks

- Fully Water-Cooled Internally - Gas Cup Recessed in Water Cooling

- Up to 500 Amps Continuous Duty Cycle

- Up to 850 Amps Continuous with Dual Power Cables

- Adaptable to Any Wire Feeder or Power Source

- Withstands Preheat Upwards of 900 Degrees

Model Explanation

- NCM-N - Normal Duty, Collet Action (Slip-In Tip), Machine Barrel - Short 5" Nozzle

- HTM-N - Heavy Duty, Threaded Tip, Machine Barrel - Short 5" Nozzle

- NCM-LRN - Normal Duty, Collet Action (Slip-In Tip), Machine Barrel - Long Rreach Nozzle

- HTM-LRN - Heavy Duty, Threaded Tip, Machine Barrel - Long Rreach Nozzle

Model Specifications

| MODEL | CURRENT CAPACITY |

WEIGHT (APPROX.) | COOLING REQUIRED |

RECOMMENDED WIRE DIA. RANGE |

INSTRUCTION MANUAL |

|---|---|---|---|---|---|

| NCM-N | 400 amps | 3.6 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

536A |

| HTM-N | 500 amps | 3.6 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCM-LRN | 400 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| HTM-LRN | 500 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

|

| NCM-X-LRN | 400 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

546 |

| HTM-X-LRN | 500 amps | 4.2 lbs | 3 quarts/min | .030"-1/8" Hard/Cored, 3/64"-3/32" AL |

Barrel Dimensions

| MODEL | LENGTH | DIAMETER OF BODY | DIAMETER OF W/C NOZZLE |

|---|---|---|---|

| NCM-LRN, HTM-LRN | 12.403" | 1.875" | 1.125" |

| NCM-N, HTM-N | 7.440" | 1.875" | 1.125" |

| NCM-X-LRN, HTM-X-LRN | 18.750" | 1.875" | 1.125" |

Ordering Information

| DESCRIPTION | CODE NO. | |

| COMPLETE ASSEMBLIES |

COMPLETE NOZZLE ONLY |

|

| NCM-N & HTM-N Straight 5" | 40704 | 48240 |

| NCM-LRN & HTM-LRN Straight Long Reach | 40786 | 48121 |

| NCM-X-LRN & HTM-X-LRN Straight Extra Long Reach | 48244 | 48145 |

| Add Footage Digit to Item Code Number for Length Required. Example: Require 40704 with 4 Ft. Utilities: 40704-4 |

||

Manuals & Downloads

Instruction Manuals

| TORCH MODELS | DOWNLOAD |

|---|---|

| NCM-N, HTM-N, NCM-LRN, HTM-LRN | 536A |

| NCM-X-LRN, HTM-X-LRN | 546 |

CAD Files & Drawings

| TORCH MODELS | CODE NO. | CAD FILE | PDF DRAWING |

|---|---|---|---|

| NCM-N, HTC-N | 40704 | 40704 | 40704 |

| NCM-LRN, HTM-LRN | 40786 | 40786 | 40786 |

| NCM-X-LRN, HTM-X-LRN | 48244 | 48244 | 48244 |

Other Documents

| DESCRIPTION | DOWNLOAD |

|---|---|

| Torch Connection Options | |

| Straight N & LRN One-Sheet |

Utility Station #45196

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

The D/F Utility Station is required for all D/F torch installations. Typical modern torch setups utilize a unitized cable assembly with a power pin. D/F torches take an alternative approach to the setup. The torches use a separate gas hose, water-in hose, Water Out & Power Cable, and casing/conduit. When one cable goes bad it is simply replaced instead of attaching an entire new unitized cable assembly; a huge cost saver! This is also where the D/F Utility Station comes into play. The gas hose, water-in hose, and Water Out & Power Cable are interfaced with the customer's existing lines via the Utility Station. The D/F torch leads plug into the front (see right) of the Utility Station. Into the back (see below) of the Utility Station go the customer's utilities. Read more on the D/F Utility Station product page.

For more information on proper use of the D/F Utility Station, and to see the various torch connection options, please download the Torch Connection Options one-sheet.